Pipe Strainers

Total 12 Records

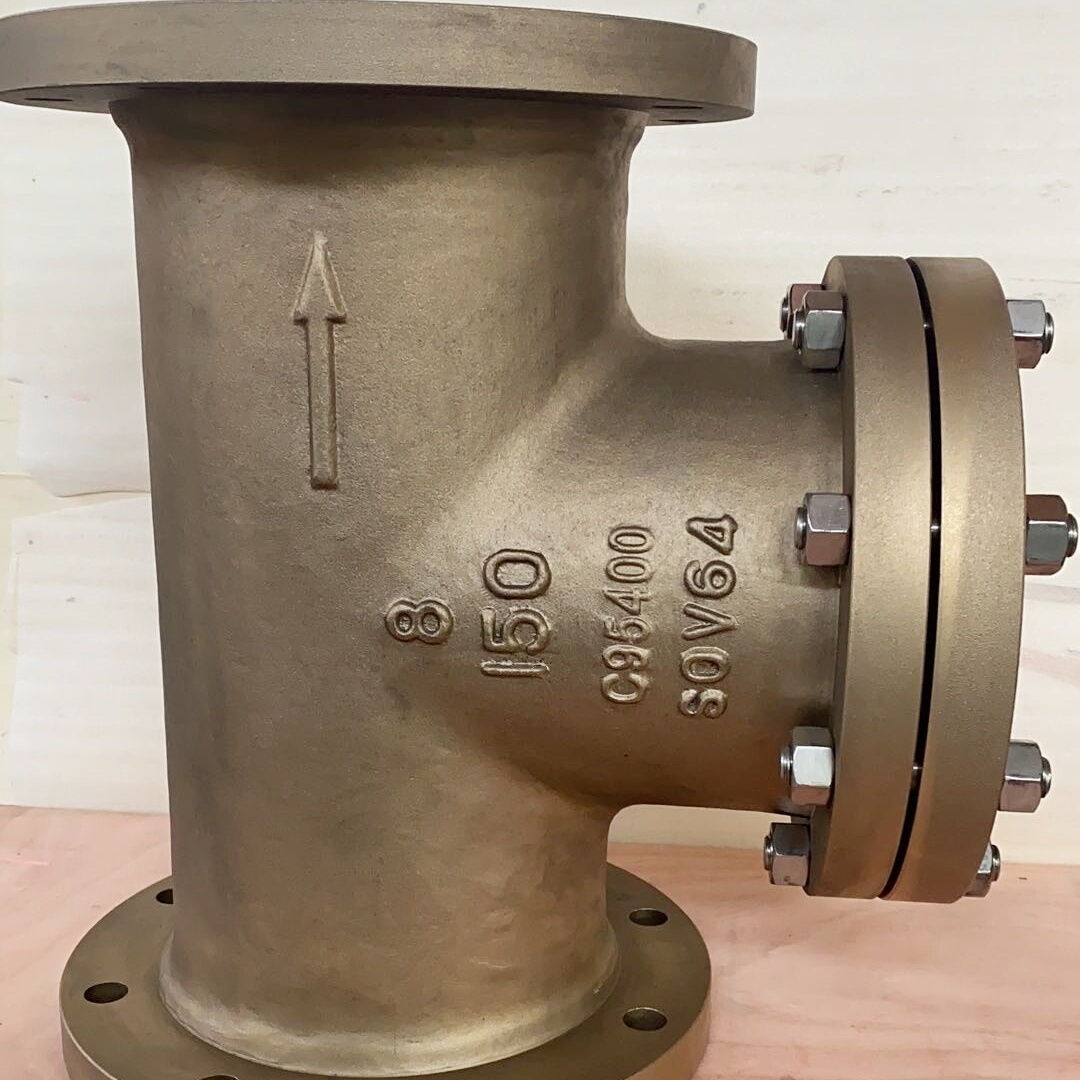

ANSI B16.34 T Strainer, Bronze B148 C95400, 8 IN, 150 LB, RF

Category: Pipe Strainers

Model no.TST-20250331

Request a quote

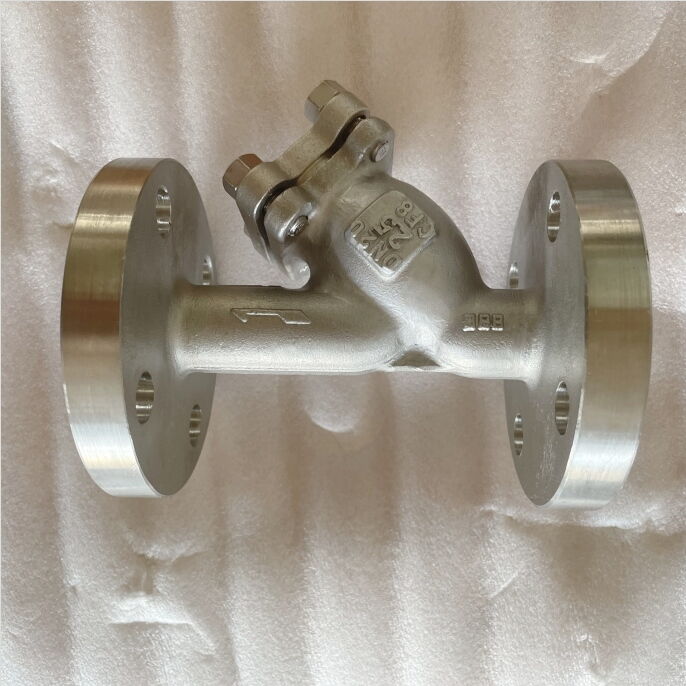

BS EN 12516 Y Strainer, A351 CF8, DN20, PN25, Bolted Bonnet

Category: Pipe Strainers

Model no.VERVO-YST-20250116-02

Request a quote

ASME B16.34 Y Strainer, ASTM A216 WCB, 6 Inch, CL 150 LB

Category: Pipe Strainers

Model no.VERVO-YST-20250116-01

Request a quote

A Y strainer is a small device that removes a small number of solid particles in the liquid, which can protect the normal operation of the device. When the fluid enters the filter cartridge with a filter, the impurities are blocked, and the clean filtrate is discharged from the strainer. When cleaning is required, just take out the detachable filter cartridge and reinstall it after treatment. Therefore, it is very convenient to use and maintain. A Y filter is an indispensable device for the pipeline system. It can filter mechanical impurities in the medium, and remove rust, sand, and a small amount of solid in liquid to protect the fittings on the pipeline from wear and blockage, which can protect the normal operation of the equipment.

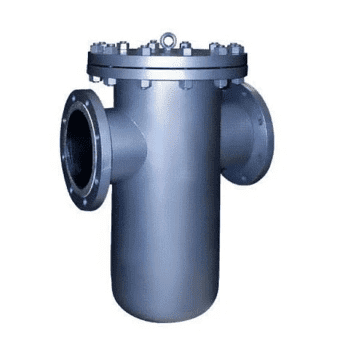

A basket filter is mainly composed of connecting pipes, cylinder bodies, filter baskets, flanges, flange covers and fasteners. It is installed on the pipeline and can remove large solid impurities in the fluid, so that the machinery and equipment including compressors, pumps and instruments can work and operate normally to stabilize the process and ensure safe production. When the liquid enters the filter basket through the cylinder, the solid particles are blocked in the filter basket, while the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is required, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reinstall it after cleaning. Therefore, it is extremely convenient to use and maintain the basket strainer.

The T-type strainer belongs to the pipeline coarse filter series and can also be used for filtering large particles of gas or other media. It can remove large solid impurities in the fluid when installed on the pipeline. The T-type filter is divided into the straight type and nonstraight type. The nonstraight T-type filter is generally installed at the right angle of the pipeline, which has the characteristics of small space, easy cleaning, and cost saving.

Cast iron strainers are often used at low temperatures and low pressure.

Bronze strainers are usually applied to salty water.

The carbon steel filter uses one or several filter media, and under a certain pressure, the liquid passes through the filter media to remove impurities to achieve the purpose of filtration. The fillers contained in it are generally quartz sand, anthracite, granular porous ceramics, manganese sand, etc. Users can choose the filler according to the actual situation. The carbon steel filter is one of the traditional water treatment methods that mainly use fillers to reduce turbidity in water, intercept suspended solids, organic matter, colloidal particles, microorganisms, chlorine smell and some heavy metal ions in the water, and purify the water.

Stainless steel strainers are used in places where there is corrosion.

Plastic strainers are suitable for places with low temperature and low pressure.

A thread filter is an indispensable device on the pipeline, and it is usually installed at the inlet of pressure-reducing valves, pressure relief valves, fixed water level valves, or other equipment to eliminate impurities in the medium and protect the valve and equipment. When the fluid enters the filter cartridge with a filter screen of a certain specification, its impurities are blocked, and the clean filtrate is discharged from the filter outlet.

The valve body of the flange filter adopts a streamlined design, which makes the medium move in a straight line in the valve cavity, with smaller fluid resistance and a larger flow area. The inside and outside of the valve is electrostatically coated with powder epoxy resin, which can effectively prevent corrosion and rust caused by the contact between the valve body and the medium. A pressure measuring hole is reserved on the valve bonnet, and a pressure testing device can be installed to test the real-time pressure of the pipeline. The size of the inlet of the filter is 1.2 to 1.3 times the diameter. The length of the filter is 1.5 times that of the conventional one, which effectively increases the flow rate and prolongs the cleaning cycle. The filter in the inner cavity is installed at an angle of 45, and the total area of the mesh opening is 3 to 4 times the nominal diameter area. The flow resistance is smaller, and the flow rate is greater. Filters with different filtration precision can be provided according to the requirements of customers.

Welded strainers are made from coiled pipes or seamless pipes by welding, with a diameter of DN150 to DN1200.

The automatic cleaning filter is widely used in drinking water, wine, petroleum products, the chemical industry and other industries because of its high efficiency and convenience. When the liquid containing solid impurities enters the automatic cleaning filter through the water inlet, the impurities are trapped on the surface of the filter, causing the pressure drop on both sides to increase, the filtration resistance to increase, and the filtration efficiency to decrease. When the impurity is trapped to a certain extent and the pressure difference on both sides of the filter reaches the set value, the pressure difference controller sends the corresponding signal to the electric valve actuator through the control cabinet, and the electric valve opens. Driven by waterpower or motor, sewage is discharged. After a period of sewage discharge, the pressure difference between the inlet and outlet of the filter decreases, and the electric valve is automatically closed to complete the backwashing process. This process is repeated to achieve the filtering effect.

In the liquid slurry conveying process, when the slurry passes through the filter, the iron impurities in the slurry are adsorbed on the magnetic bar sleeve by the great magnetic effect of the magnetic rod, which greatly reduces the iron impurities in the slurry and ensures that the content of iron impurities can be effectively controlled in the next process. Magnetic filters are widely used in pigments, dyes, petrochemicals, pharmaceuticals, food, plastics and other industries. They can effectively remove magnetic metal impurities, reduce iron ion content in products, and improve the quality of products during liquid slurry transportation. Magnetic filters have the advantages of small sizes, light weights, convenient installation and operation.

The oxygen filter is a special filter specially designed for the oxygen manufacturing pipeline. The filter is composed of a diverter cone and a filter pipe. The thrust of the water flow mainly plays a role in gas diversion, thus avoiding the rupture of the filter caused by the front. Gas filters are widely used in gas filtration in industrial production departments, such as air, nitrogen, oxygen and other gases. An oxygen filter is a special filter specially designed for the oxygen production pipeline.

Temporary filters are used for temporary filtering and belong to the standard filter. When ordering, it is necessary to well indicate information such as the product name, nominal diameter, material, pressure, flange standard, filtration, accuracy, etc.