Check Valves

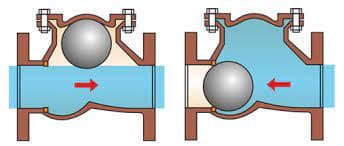

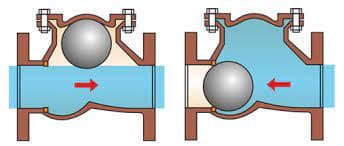

A check valve is also known as a one-way valve, which is used to prevent the medium in the pipeline from flowing backward. Check valves belong to automatic valves and are mainly used on pipelines with a one-way flow of the medium, and only allow the medium to flow in one direction to prevent accidents.

The water enters from the inlet of the check valve, and after being squeezed by the disc, the water flows to the outlet. The outlet of the check valve has the function of blocking the water flow in reverse. From the flow direction of the check valve, the flow enters the check valve clockwise. The process of using the pressure of the medium to control the opening and closing of the disc is called the working principle of the check valve.

There are many types of check valves, and different types of check valves are suitable for different occasions. Generally, the occasions where check valves are often used are mainly as follows:

1. Water supply pipes for high-rise buildings

2. Pipelines with a certain chemical corrosive medium

3. Sewage pipes

4. Water supply and drainage systems

5. Submersible, drainage and sewage pumps

6. Domestic water pipes

7. Pipelines in petroleum, chemical, metallurgical and other industrial sectors

1. Water supply pipes for high-rise buildings

2. Pipelines with a certain chemical corrosive medium

3. Sewage pipes

4. Water supply and drainage systems

5. Submersible, drainage and sewage pumps

6. Domestic water pipes

7. Pipelines in petroleum, chemical, metallurgical and other industrial sectors

Total 227 Records

ASTM A182 F304 Y Check Valve, ASME B16.34, 1/2 IN, CL800, SW

Category: Check Valves

Model No.CKV-20250920

Request a quote

API 594 Dual Plate Check Valve, CF3M, 2 Inch, 150 LB, Wafer

Category: Check Valves

Model No.DPCV-20250913

Request a quote

Pneumatic Slow Closing Check Valves, A216 WCB, DN250, PN10

Category: Check Valves

Model No.CKV-20250627-02

Request a quote

Slow Closing Butterfly Check Valve, F304, 52 IN, 150 LB, RF

Category: Check Valves

Model No.CKV-20250627-01

Request a quote

Silent Check Valves, ASTM A216 WCB, DN250, PN25, RF Flanged

Category: Check Valves

Model No.SCV-20250620-02

Request a quote

Silent Check Valve, GB/T 21387, A216 WCB, DN200, PN16, RF

Category: Check Valves

Model No.SCV-20250620-01

Request a quote

Slow Closing Butterfly Check Valve, A216 WCB, DN600, PN10

Category: Check Valves

Model No.CKV-20250613-04

Request a quote

Micro Resistance Check Valve, CJ/T 154, QT450-10, DN500, PN10

Category: Check Valves

Model No.CKV-20250613-03

Request a quote

Slow Closing Check Valve, CJ/T 154, QT450, DN800, PN10, RF

Category: Check Valves

Model No.CKV-20250613-02

Request a quote

Micro Resistance Slow Closing Check Valve, CF3M, DN400, PN10

Category: Check Valves

Model No.CKV-20250613-01

Request a quote

Butterfly Slow Closing Check Valve, A216 WCB, DN700, 150 LB

Category: Check Valves

Model No.CKV-20250530-02

Request a quote

Slow Closing Butterfly Check Valve, CJ/T 282, WCB, DN800, RF

Category: Check Valves

Model No.CKV-20250530-01

Request a quote

Because the sealing part is a rubber-coated sphere, the ball check valve has good sealing performance, reliable operation, and good water hammer resistance. The sealing part can be a single ball or multiple balls, a ball check valve with large sizes is available. However, its sealing part is a hollow sphere covered with rubber, which is not suitable for high-pressure pipelines, but only for medium-pressure and low-pressure pipelines. Since the shell of the ball check valve can be made from stainless steel, and the hollow sphere of the sealing part can be covered with polytetrafluoroethylene engineering plastics, it can also be applied to pipelines with general corrosive media. The valve disc of the ball check valve is spherical, and its principle is similar to that of the lift check valve.

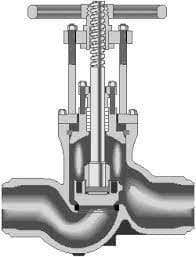

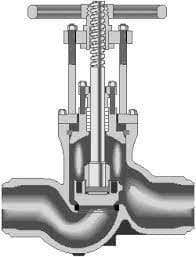

The globe check valve is a multi-purpose valve with both functions of globe valves and check valves. Its structure is similar to that of the globe valve, but its stem and disc are not fixed. When the valve stem is lowered to press the disc tightly on the valve seat, it acts as a globe valve; when the valve stem rises, it acts as a check valve. On pipelines that need to install globe valves (or gate valves) and check valves at the same time, such as the outlet end of water pumps, or in places where the installation position is limited, such as ships, installing globe check valves can save installation costs and space.

A diaphragm check valve is a type of check valve that has developed rapidly in recent years. Although the operating temperature and working pressure of the diaphragm check valve are limited by the diaphragm material, it has good performance in preventing water hammer, simple manufacture, low cost and low noise, and is especially suitable for occasions with low pressure and temperature. Diaphragm check valves have a variety of structural forms. Diaphragm check valves are divided into flat diaphragm check valves, duckbill check valves and conical diaphragm check valves.

The foot valve is a kind of check valve, which is a low-pressure flat valve. Its function is to ensure that the liquid flows in one direction in the suction pipe, so that the pump can work normally. When the pump stops working for a short time, the liquid cannot return to the water source tank, ensuring that the suction pipe is filled with liquid to facilitate the starting of the pump. The foot valve plays a role in preventing water from flowing backwards. The foot valve can be divided into plastic foot valves and metal foot valves according to the material, and can also be classified into ordinary foot valves and bottom valves with backwash water flow. The bottom valve is mainly used in pumps and other mechanical equipment for slurry treatment. Usually, the bottom valve is installed at the bottom of the pump's underwater suction pipe to prevent the slurry from flowing back.

The double-disc butterfly check valve is also a swing check valve, but it has double discs which close under the action of a spring. The fluid from bottom to top pushes the valve disc. The valve has a simple structure, and the wafer is installed between two flanges, with small dimensions and light weight. The double disc of the double-lobe butterfly check valve makes the sealing and operation of the valve seat more effective. The long-arm spring of the double disc butterfly check valve enables the disc to open and close without rubbing against the valve seat, and the spring acts independently to close the disc (for a size of DN150 and above). The hinged support sleeve of the double disc butterfly check valve reduces friction and minimizes water hammer when aborted by the independent disc.

The double disc butterfly check valve also has special structural features, which makes this valve a high-performance non-impact check valve. These features include no-clean opening, independent springs for most valve sizes, and independent disc support systems. Some check valves do not have these features. Double disc butterfly check valve can also be designed as lug type, double flange and extended valve body.

The double disc butterfly check valve also has special structural features, which makes this valve a high-performance non-impact check valve. These features include no-clean opening, independent springs for most valve sizes, and independent disc support systems. Some check valves do not have these features. Double disc butterfly check valve can also be designed as lug type, double flange and extended valve body.

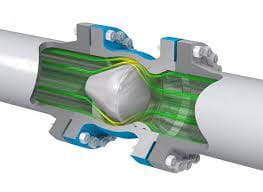

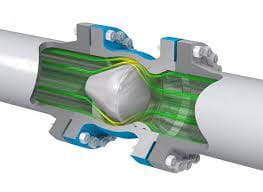

(1) Rapid opening and closing: the disc of the axial flow check valve has a short stroke, and the streamlined structure design has low resistance, which can realize the purpose of rapid closing.

(2) Noiseless: The opening and closing of the disc is in a dynamic balance system. The valve operates in a balanced manner. The reverse flow speed is small at the moment of closing, and the spring reset makes the valve open and close without impact, reducing noise and the effect of the water hammer.

(3) Excellent sealing performance: the disc has light weights, and the light-weight, low-inertia disc has little impact on the valve seat after being closed in a short stroke, which can effectively reduce the leakage caused by damage to the sealing surface of the valve seat.

(4) Low operating energy consumption: The fluid flowing through the axial flow check valve can fully open the valve only by overcoming the spring force, and the critical flow rate required by it is much lower than that required by the swing check valve. Under the premise of fully ensuring the circulation area, the operating energy consumption can be reduced to the greatest extent.

(5) Small fluid resistance: The axial flow structure and the streamlined flow channel on the flow surface can ensure that the fluid is in a laminar flow state, so that the valve has a small flow resistance coefficient and saves energy.

(6) Flexible installation: Compared with other types of check valves of the same size, the axial flow check valve has a short length, light weights, small installation positions, and can be installed horizontally, vertically and at any angle.

(2) Noiseless: The opening and closing of the disc is in a dynamic balance system. The valve operates in a balanced manner. The reverse flow speed is small at the moment of closing, and the spring reset makes the valve open and close without impact, reducing noise and the effect of the water hammer.

(3) Excellent sealing performance: the disc has light weights, and the light-weight, low-inertia disc has little impact on the valve seat after being closed in a short stroke, which can effectively reduce the leakage caused by damage to the sealing surface of the valve seat.

(4) Low operating energy consumption: The fluid flowing through the axial flow check valve can fully open the valve only by overcoming the spring force, and the critical flow rate required by it is much lower than that required by the swing check valve. Under the premise of fully ensuring the circulation area, the operating energy consumption can be reduced to the greatest extent.

(5) Small fluid resistance: The axial flow structure and the streamlined flow channel on the flow surface can ensure that the fluid is in a laminar flow state, so that the valve has a small flow resistance coefficient and saves energy.

(6) Flexible installation: Compared with other types of check valves of the same size, the axial flow check valve has a short length, light weights, small installation positions, and can be installed horizontally, vertically and at any angle.

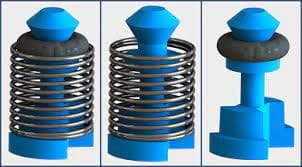

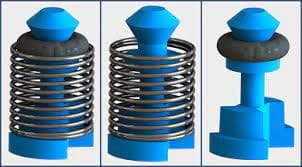

Spring-loaded check valves refer to a kind of valve whose opening and closing parts are circular valve discs, which can block the reverse flow of the medium by acting on its weight and medium pressure. Spring check valves are also used on pipelines of supply auxiliary systems where the pressure may rise above system pressure.

The wafer check valve is small; the disc stroke is short, and it is assisted by a spring to close the valve. The valve closing speed is fast. The resistance of the wafer check valve is small, and the fluid resistance coefficient ξ is 2.6 to 2.7. With the increase in the valve diameter, the fluid resistance coefficient is reduced. The wafer check valve can be installed horizontally or vertically. It has light weights, and there is no need to set support. The opening of the wafer check valve is very small, and the disc can be fully opened under a small pressure difference; the wafer check valve has an overall structure, which is simple and compact, and the impact force is small when the valve is closed. The wafer check valve has small water hammer pressure, long service life and good reliability.

1. The structure length is short, which is only 1/4 to 1/8 of the traditional flange check valve.

2. The wafer check valve has small sizes and light weights; its weight is only 1/4 to 1/20 of the traditional flange check valve.

3. The disc closes quickly, and the water hammer pressure is small.

4. Horizontal or vertical pipes can be used, which are easy to install.

5. The flow channel is smooth, and the fluid resistance is small.

6. The wafer check valve has sensitive action and good sealing performance.

7. The disc stroke is short, and the closing impact is small.

8. The wafer check valve has a simple and compact overall structure and beautiful appearance.

9. The wafer check valve has long service life and reliable performance.

2. The wafer check valve has small sizes and light weights; its weight is only 1/4 to 1/20 of the traditional flange check valve.

3. The disc closes quickly, and the water hammer pressure is small.

4. Horizontal or vertical pipes can be used, which are easy to install.

5. The flow channel is smooth, and the fluid resistance is small.

6. The wafer check valve has sensitive action and good sealing performance.

7. The disc stroke is short, and the closing impact is small.

8. The wafer check valve has a simple and compact overall structure and beautiful appearance.

9. The wafer check valve has long service life and reliable performance.

Lift check valves can be divided into vertical check valves and horizontal check valves. The valve disc of the lift check valve is shaped like a piston, so it is also called a piston check valve. When the flow starts, it is pushed by the upstream fluid, disengages the valve seat, and opens the flow path; when the flow stops, the disc returns to the valve seat under the action of gravity to cut off the backflow.

Swing check valves are divided into single-disc check valves, double-disc check valves and multi-disc check valves. The fluid resistance of the swing check valve is smaller than that of the lift check valve. It is suitable for occasions with large diameters. The installation position is not limited, and it is usually installed in horizontal pipelines. Single disc swing check valves are usually used in pipelines with medium diameters. When a single disc swing check valve is selected for a large-diameter pipeline, to reduce water hammer pressure, it is best to use a slow-closing check valve that can reduce the water hammer pressure. The double disc swing check valve is suitable for pipelines with large and medium diameters. The double-disc swing check valve has small structure and light weight, and is a faster check valve; the multi-disc swing check valve is suitable for pipelines with large diameters.

The butterfly check valve is a straight-through check valve, which is suitable for pipelines with low pressure and large diameters, and the installation occasion is limited. The working pressure of the butterfly check valve cannot be very high, but the nominal diameter can be very large, which can reach more than 1200mm; the nominal pressure is below 6.4MPa. The butterfly check valve can be made into a wafer type, which is generally installed between the two flanges of the pipeline in the form of a wafer connection.

1. A threaded check valve has short structure, small volume and light weight.

2. The disc closes quickly, and the water hammer pressure is small.

3. The flow channel is smooth. The fluid resistance is small; the action is sensitive and the sealing performance is good.

4. It is easy to install and can be installed on pipelines in both horizontal and vertical directions.

2. The disc closes quickly, and the water hammer pressure is small.

3. The flow channel is smooth. The fluid resistance is small; the action is sensitive and the sealing performance is good.

4. It is easy to install and can be installed on pipelines in both horizontal and vertical directions.

Threaded check valves are widely used in chemical, petrochemical, petroleum, papermaking, mining, electric power, liquefied gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment, electronic industry, urban construction and other fields.

A flanged check valve is also called a flanged one-way valve, which is connected by flange ends. The inlet and outlet flanges of the valve body are aligned with the flanges at both ends of the pipe and connected by bolts. A flanged check valve is widely used for pipelines in municipal facilities, construction, petrochemical, electric energy and metallurgy

When the medium flows in the specified direction, the valve stem is pushed by the force of the medium to make the medium flow; when the pressure at the inlet end is lower than the pressure at the outlet end, depending on the weight of the valve stem and the pressure generated by the reverse flow of the medium, the valve disc can be closed, which can prevent the backflow of the medium.

Welded check valves include butt-welded check valves and socket welded check valves. Butt-welded check valves are widely used for food, medicine, textile, electric power, shipbuilding, metallurgy, construction, petroleum, sewage and other fields. A socket-welded check valve has a recessed area where the pipe can be inserted.

Stainless steel check valves are divided into lift stainless steel check valves, swing stainless steel check valves, disc stainless steel check valves and various wafer stainless steel check valves. When the check valve is installed on the pipeline, it becomes one of the fluid parts of the complete pipeline. The opening and closing process of the valve disc is affected by the transient flow conditions of the system in which it is located; in turn, the characteristics of the valve disc’s sealing influence the fluid flow.

The cast iron check valve is suitable for most of the horizontal pipelines in the tank, which can automatically prevent the reverse flow of the medium and protect the upstream equipment. The cast iron lifting check valve is used on the pipeline of water and steam medium with working temperatures less than and equal to 200°C, and is used for one-way opening and closing to prevent the medium from flowing backward.

PP check valves have light weight, good corrosion resistance, beautiful appearance, easy installation, wide range of applications. They can be used for media such as water, air, oil, and corrosive chemical liquid.

Carbon steel check valves are durable and can easily withstand high pressure and temperatures. The pressure required to open the valve is an important aspect to consider when purchasing a carbon steel check valve. If the required differential pressure is high, there will be a pressure drop across the valve.