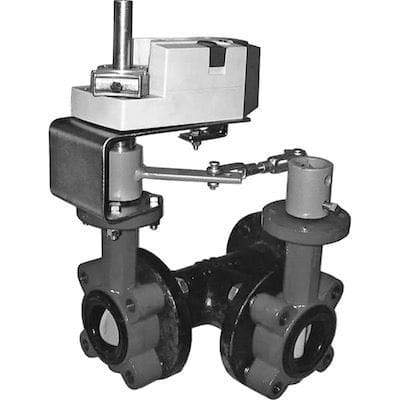

The electric butterfly valve consists of an electric actuator and a butterfly valve. The opening and closing of the butterfly valve are driven by the rotation of the electric actuator. At the same time, the electric butterfly valve also has a manual operation function, which is convenient in the event of a power failure and can be operated by manually operation to open and closed the butterfly valve. Electric butterfly valves are used for canning and bottle systems, beer brewing and beverage technology, the chemical industry, fluid mixing devices, food, industrial concrete and cement industry, vacuum technology, water treatment device, laundry, medical equipment, boiler feed water, etc.

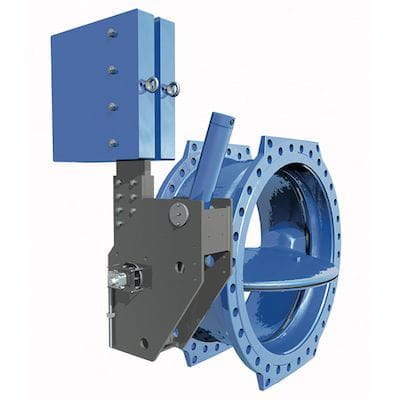

The pneumatic butterfly valve is composed of the pneumatic actuator and the butterfly valve. Because of the characteristics of the butterfly valve, such as lightweight, simple structure and easy operation, it is often installed and used on the large-diameter low-pressure pipeline. Pneumatic butterfly valves can be divided into single-acting pneumatic butterfly valves and double-acting pneumatic butterfly valves. The execution speed of the pneumatic butterfly valve is relatively fast. It is not easy to be damaged due to jamming in the action, and does not require workers. The pneumatic butterfly valve can not only be used as a shut-off valve, but also can be equipped with a valve positioner to achieve the function of adjusting and controlling the pipeline medium.

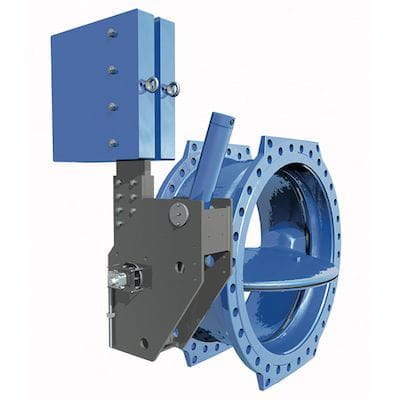

Hydraulic butterfly valves are mainly used in high-safety systems such as steam turbine extraction pipelines, blast furnace gas residual pressure power generation units, and industrial pipelines with media such as seawater, sewage, flue gas, air, and oil as emergency shut-off valves.

Manual butterfly valves need to be manually operated to open or close. In view of this mode of operation, manual butterfly valves are not suitable for installation in high altitudes or dangerous working conditions. The most important thing in the installation environment of the manual butterfly valve is to facilitate manual operation. The valve’s installation location must be convenient for personnel’s daily operation and future maintenance. The best location for manual valve installation is about 1.2 meters from the ground. Normally, the manual butterfly valve is suitable for the following occasions: adjusting the flow, mud and medium containing solid particles, requiring a short valve structure length, requiring fast opening and closing speed and small pressure difference.

There are two different soft-seated butterfly valves. One is that the sealing pair is composed of non-metallic soft material to non-metallic soft material, and the other is that the sealing pair is composed of metal and non-metal.

The sealing pair of the metal seated butterfly valve is composed of metal to metal.

Forced-sealed butterfly valves are classified into elastic-sealed butterfly valves and torque-sealed butterfly valves. The sealing specific pressure of the forced sealed butterfly valve is generated by the elasticity of the valve seat or valve plate when the valve plate squeezes the valve seat in a closed state. The sealing specific pressure of the torque-sealed butterfly valve is generated by the torque applied to the valve shaft.

The sealing-specific pressure of the pressure-sealed butterfly valve is generated by the pressure of the elastic sealing element on the valve seat or valve plate.

The sealing specific pressure of the automatic sealed butterfly valve is automatically generated by the medium pressure.

The working pressure of the vacuum butterfly valve is lower than the standard atmospheric pressure.

Low-pressure butterfly valves have nominal pressure of less than 1.6MPa.

Medium-pressure butterfly valves have nominal pressure between 2.5 to 6.4MPa.

High-pressure butterfly valves have nominal pressure between 10.0 to 80.0MPa.

Ultra-high pressure butterfly valves have nominal pressure PN greater than 100MPa.

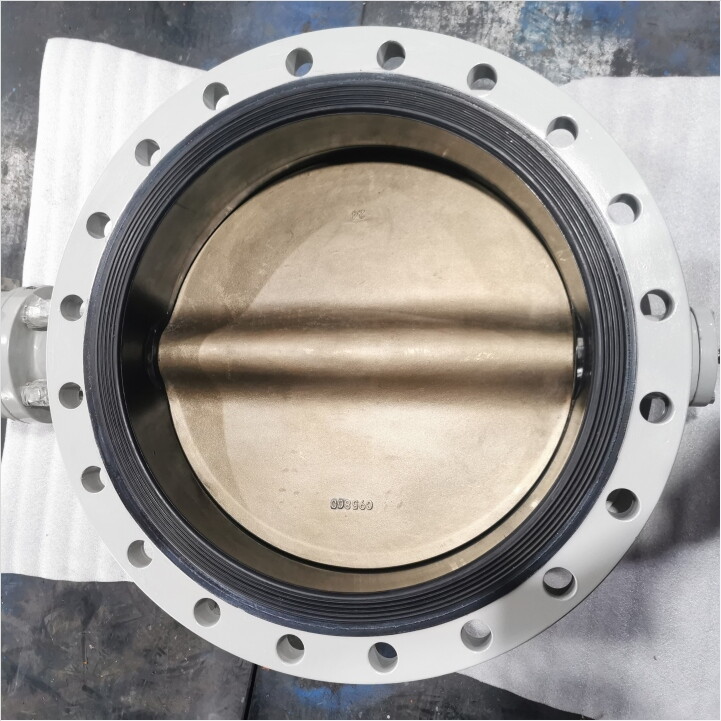

The butterfly plate of the wafer butterfly valve is installed in the direction of the pipeline’s diameter. Wafer butterfly valves have two sealing types: elastic sealing and metal sealing. For elastic sealing valves, the sealing ring can be embedded in the valve body or attached to the periphery of the butterfly plate.

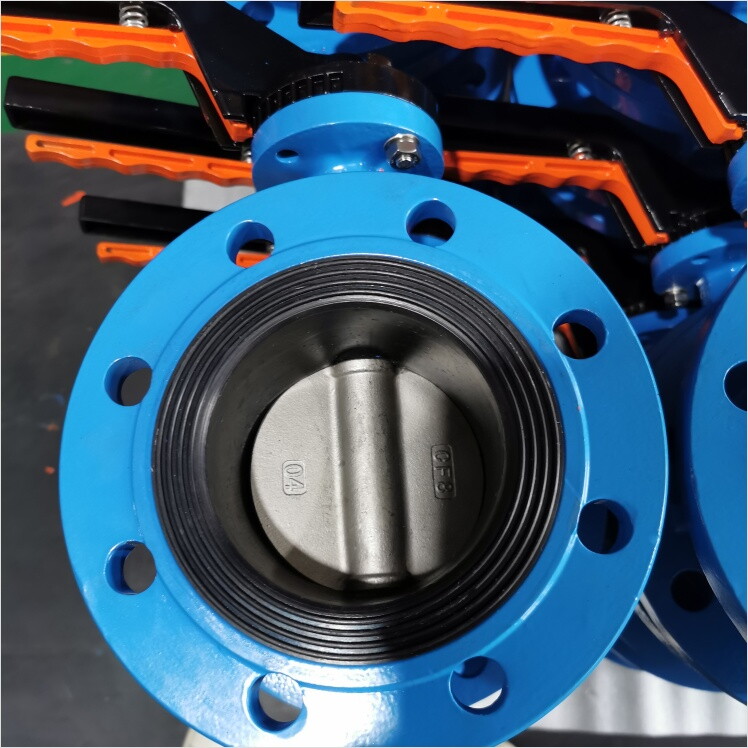

The flanged butterfly valve has a vertical plate, and the valve stem has an integral metal seal. The sealing ring of the valve has a composite structure of flexible graphite plates and stainless steel plates, installed on the valve body, and the sealing surface of the butterfly plate is surfaced with stainless steel. The sealing ring of the soft seated valve is made of nitrile rubber and is installed on the butterfly plate.

The lug butterfly valve can be driven by handwheels, worm gears, pneumatics and electricity; the connection method can be flange or wafer; the structure can be single eccentric, centerline, double eccentric, triple eccentric; metal seats and soft seats can be adopted. The lug butterfly valve can be made from cast steel or stainless steel.

A welded butterfly valve is widely used in pipelines with medium temperatures less than and equal to 300°C and nominal pressure of 0.1Mpa in the production process of building materials, metallurgy, mining and electric power to open and close the valve or adjust the medium volume.