Globe Valves

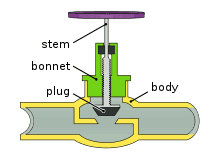

The working principle of globe valves

b. The sealing surface is less worn and scratched, and the sealing performance is good. When the valve is opened and closed, there is no relative sliding between the valve disc and the sealing surface of the valve body (except the conical sealing surface), so the wear and abrasion are not serious; the sealing is good, and the service life is long.

c. The opening height is small, generally only 1/4 of the diameter of the valve seat channel; the structure is compact, and the installation space is saved.

ASME B16.34 Globe Valves, A182 F91, 1-1/2 IN, 1500 LB, OS&Y

API 602 Globe Valves, ASTM A105N, 1 Inch, CL800 LB, OS&Y, SW

Bellow Sealed Globe Valves, API 602, A105N, 1-1/2 IN, 300 LB

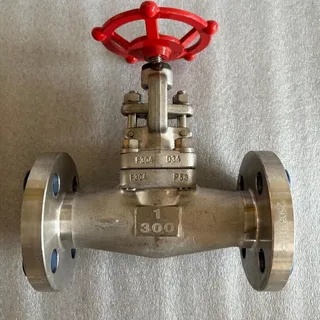

ASTM A182 F304 Globe Valve, API 602, 1 IN, CL300, RF Flanged

API 602 Globe Valves, ASTM A350 LF2, 2 Inches, CL300 LB, RF

ASTM A182 F22 Globe Valves, API 602, 1500 LB, 2 Inch, BW

High Temperature Globe Valve, A182 F22, 800 LB, 2-1/2 Inch

Carbon Steel ASTM A350 LF2 Globe Valve, ISO 15761, PN63, DN20

ASTM A182 F304 Globe Valve, API 602, 150 LB, 1 Inch, OS&Y

ASTM A105N Bellows Globe Valve, 600 LB, 1 Inch, API 602, BB

API 602 Globe Valve, ASTM A105N, 1/2 Inch, 150 LB, OS&Y

API 602 Stainless Steel Globe Valve, A182 F304,1/2 IN,150 LB

| Sizes | DN15 to DN200 |

| Temperature ranges | -20℃ to 600℃ |

| Pressure | PN16 to PN320 |

| Materials of valve bodies | WCB, 304, 316, WC6, WC9 |

| Materials of valve stems | SS304, WC6, WC9 |

| Materials of valve bonnets | They have the same materials as the body. |

| Materials of valve seats | Stainless steel or alloy ammonia |

| Connections | Welding |

| Applications | Used for water, oil, steam, and some corrosive liquids |

Pressure seal bonnet globe valves have elastic wedges and the valve stem has the function of upper sealing. The sealing surface is surfaced with CR13, cemented carbide, which is wear-resistant, high-temperature resistant and has a long service life.

In the opening and closing process, the friction between the sealing surfaces is small; the straight-through globe valve is wear-resistant, has a small opening height, and good manufacturing process performance. Compared with the gate valve, the structure of the globe valve is simpler, and the manufacture and maintenance are convenient.

The common size and pressure of angle globe valves are usually DN50 to 250 (NPS 2 to 10), Class 150 to 800. Small copper alloy threaded angle globe valves are widely used in clean water. Most industrial angle globe valves are bolted bonnet globe valves made from cast steel, bronze, stainless steel and duplex steel.

A needle globe valve is used for precise flow control. The valve disc is usually integrated with the valve stem, and it has a very high-precision needle head matched with the valve seat. Moreover, the thread pitch of the stem thread of the needle globe valve is thinner than that of the ordinary globe valve. In general, the size of the needle globe valve seat hole is smaller than the pipe size. Therefore, it is only used in pipelines with small nominal diameters.

High-temperature and high-pressure power station globe valves

The connection between the valve body and the bonnet of the high-temperature and high-pressure power station globe valve adopts pressure self-tightening sealing or clamping. The connection between the valve body and the pipeline is butt welding, and the valve body is mostly made from chrome molybdenum steel or chrome molybdenum vanadium. The sealing surface is mostly surfacing hard alloys. Therefore, this kind of valve is resistant to high temperature and high pressure, and has good heat resistance; the sealing surface is resistant to wear, abrasion, corrosion, and has good sealing performance and long service life. It is most suitable for pipelines with high temperature and high pressure, steam, petroleum products and superheated steam in thermal power industrial systems, petrochemical systems and metallurgy.

The opening and closing part of the fluorine-lined globe valve is a plug-shaped valve disc, and a sealing surface is a plane or a conical surface; the valve disc moves linearly along the center line of the fluid. The movement of the valve stem includes lifting stems and lifting rotating stems. The valve stem of lifting stems rises and falls, but the handwheel does not rise and fall. The handwheel of lifting rotating stems rotates and lifts together with the valve stem, and the nut is arranged on the valve body. Fluorine-lined globe valves are suitable for aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids and strong oxidants with various concentrations at a temperature of -50°C, and can also be applied to the pipeline with strong alkali organic solvents with various concentrations, corrosive gases and liquids.

Insulation globe valves are mainly used in petroleum, chemical, metallurgy, pharmaceutical and other systems to transport high-viscosity medium that will solidify at room temperatures. The side and bottom of the insulation globe valve are provided with two connection ports for the thermal insulation jacket. Insulation globe valves are widely used in various systems such as petroleum, chemical, metallurgy, and pharmaceutical systems.

The connection between the valve body and the bonnet, the installation of the stuffing box, the valve stem nut, and the upper seal of API globe valves should be all designed in strict accordance with the API design. The selection of materials, testing of valves should be carried out based on the requirements. API globe valves are widely used in petrochemical pipelines, electric power, metallurgy, textile and other systems.

Oxygen pipeline globe valves should be strictly designed according to the requirements of the oxygen pipeline. The stuffing box should be well sealed, and external dirt must not enter the stuffing box. The flanges at both ends of the valve body have grounding devices. After installation on the pipeline, they should be grounded to prevent static electricity and igniting. The valve shell is made from austenitic stainless steel or copper, which has good electrical conductivity and is not prone to static ignition. The sealing is PTFE, which is a soft seal, with good sealing performance and zero leakage for the gas. The valve is strictly degreased by carbon tetrachloride before assembly, and there is absolutely no grease and dirt, which will not cause a static fire. The valve is suitable for oxygen pipelines in metallurgical systems, and oxygen pipelines in other industries.

Bellows globe valves are also called bellows seal globe valves. Through automatic rolling welding, a metal barrier is formed between the fluid and the atmosphere to ensure zero leakage of the valve stem. The bellows globe valve adopts a bellows structure inside, and the lower end of the stainless steel bellows is welded to the valve stem to prevent the process fluid from eroding the valve stem. The other end is placed between the valve body and the valve bonnet to form a static seal. The double sealing will avoid leakages of the valve stem packing if the bellows fails. The bellows is welded to the valve stem to maintain stable operation and avoid vibration of the valve stem caused by the vibration of the valve plug. Bellows globe valves are most suitable for pipelines with steam, flammable, explosive, heat transfer oil, high purity, toxic and other media.

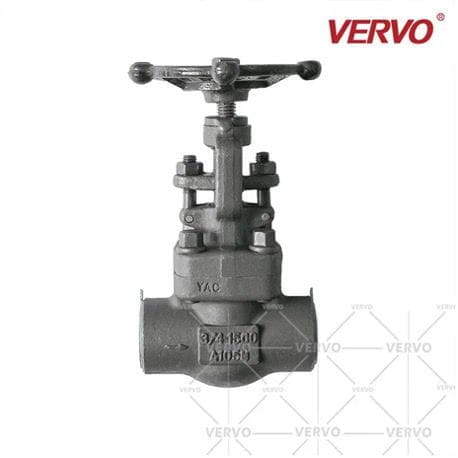

Forged steel globe valves are designed according to the standards of the American Petroleum Institute. The valve body and bonnet are made from carbon steel or stainless steel by forging. The valve body and bonnet are connected by bolts, threaded connections and welding, and there are upper threaded stems and lower threaded stems. The sealing pair is made from steel, stainless steel acid steel to STL hard alloy and the packing flexible graphite or PTFE. The valve can be connected by flanges, threads, socket welding and butt welding. The forged globe valve is widely used in the equipment and pipelines of petrochemical, electric power, chemical and other departments. The working media is steam, petroleum products and corrosive media.

This valve is specially designed for pipelines or equipment for petroleum-liquefied gas. The requirement of fire protection is paid attention to. The packing is made from polytetrafluoroethylene, which has reliable sealing and no leakage. The sealing pair is made from polytetrafluoroethylene or nylon, which is a soft seal with reliable sealing. Petroleum liquefied gas globe valves are suitable for liquefied petroleum gas pipeline systems as an opening and closing device, and also suitable for other pipelines whose temperature is less than or equal to 80℃.

The cryogenic globe valve usually refers to the valve whose working temperature is lower than

-110°C, which is widely used in liquefied natural gas, liquefied petroleum gas and other low-temperature industries. Valve discs of cryogenic globe valves move along the centerline of the valve seat. According to this movement of the valve disc, the change of the valve seat port is proportional to the valve disc stroke. Cryogenic globe valves have a relatively short opening or closing stroke, and a function of very reliable cutting off, which makes them very good for regulating fluids.

The anti-scour stop valve is suitable for water and steam pipelines as an opening and closing device. It is often applied to drainage for steam turbines, feed water, heaters, boiler drainage and superheaters. To avoid high-speed scouring of the medium, the valve adopts a reverse flow, and the valve sealing pair adopts the first throttling to block the dirt, and then uses the throttled medium to make the sealing surface clean by itself, thus completely solving the internal leakage.