Development of Low-Temperature High-Manganese Steel for Cryogenic Valves

Feb 10, 2026

In cryogenic industrial applications such as liquid hydrogen, liquefied natural gas, and ethylene processing facilities, materials are subjected to significant fluctuations in temperature and pressure. Most metallic materials undergo thermal expansion and contraction, and their impact toughness decreases rapidly at low temperatures, resulting in reduced safety and service performance of cryogenic equipment. Therefore, the development of cryogenic materials that combine excellent low-temperature performance, manufacturability, and economic viability is of great importance for accelerating and advancing the localization of cryogenic equipment.

In this study, the chemical composition, casting process, heat treatment, and welding procedures of high-manganese steel were systematically designed and comparatively evaluated to determine the optimal material design and technical parameters. The performance of the developed material was compared with that of 18Cr–8Ni austenitic stainless steel and 9% Ni steel, which are commonly used under cryogenic service conditions. The results show that the newly developed low-temperature high-manganese austenitic cast steel ZG45Mn24C14CuDR exhibits excellent mechanical properties, superior low-temperature impact toughness, good weldability, and strong resistance to plastic deformation, while also offering significant cost advantages. Consequently, this material represents a novel ultra-low-temperature structural material with high strength and excellent cryogenic toughness, making it suitable for cryogenic valves.

In cryogenic industrial applications, the selection of materials for cryogenic valves is of critical importance. Typical applications include liquid hydrogen and liquid helium systems, natural gas liquefaction plants, LNG storage, transportation, and regasification facilities, as well as ethylene and liquid nitrogen installations. From the perspectives of cost and operational efficiency, cryogenic media are generally stored and transported in critical or supercooled states. Heat exchange between cryogenic pipelines or equipment and the surrounding environment, along with pressure adjustments required by process conditions, inevitably causes changes in the physical state of the cryogenic medium. These phase and state changes involve heat absorption and release, consequently affecting the temperature and pressure of the medium within the pipeline. As a result, cryogenic piping systems experience significant fluctuations in both temperature and pressure. Most metallic materials possess the inherent property of thermal expansion and contraction, with impact toughness decreasing sharply as temperature decreases. Consequently, the selection of materials for cryogenic valves must account not only for their physical and mechanical properties over a wide temperature range, but also for weldability, resistance to plastic deformation under thermal cycling, chemical stability, economic feasibility, and environmental sustainability. Furthermore, environmental factors, including the carbon emissions associated with material production and processing, are gaining increasing significance.

These factors primarily affect the performance of cryogenic valves in three ways:

(1) the reduced toughness of pressure-bearing and pressure-controlling components at low temperatures, which can result in material embrittlement.

(2) Deformation resulting from thermal expansion and contraction during temperature fluctuations, which can potentially compromise valve sealing performance or cause jamming and wear of moving components.

(3) Structural design challenges associated with cold energy loss from cryogenic media and the freezing of operating components exposed to the atmosphere. Careful consideration and management of all three factors are essential to ensure the safe and reliable operation of cryogenic valves.

Representative applications of cryogenic valves include LNG storage, transportation, and regasification facilities, as well as ethylene plants and air separation units. The liquefaction temperature of natural gas is approximately −163 °C, and LNG is typically stored at around −165 °C. Ethylene maintains higher purity and stability at low temperatures and is generally stored at approximately −110 °C. In physical gas liquefaction and separation processes, liquid oxygen, liquid nitrogen, and liquid hydrogen must likewise be separated and stored under cryogenic conditions. Currently, ultra-low-temperature equipment and storage tanks are primarily fabricated from high-nickel alloy steels (9% Ni), aluminum alloys, and austenitic stainless steels. Depending on the specific service conditions, other low-temperature-resistant alloys—such as 6% Mo steels, Ni–Cr–Fe, Ni–Fe–Mo, and Ni–Cu alloys—are also used. Considering material cost and overall applicability, Table 1 summarizes several commonly used casting materials for cryogenic valves, along with their key performance parameters.

|

Materials |

US Standard |

Chinese Standard |

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Average Impact Energy at Minimum Operating Temperature (J) |

Minimum Operating Temperature (°C) |

|

Carbon Steel |

ASTM A352 |

— |

LCB |

450–620 |

≥240 |

24 |

18 |

−46 |

|

Carbon–Molybdenum Steel |

— |

JB/T 7248 |

LC1 (0.5% Mo) |

450–620 |

≥240 |

24 |

18 |

−59 |

|

2.5% Nickel Steel |

— |

— |

LC2 (2.5% Ni) |

485–655 |

≥275 |

24 |

20 |

−73 |

|

3.5% Nickel Steel |

— |

— |

LC3 (3.5% Ni) |

485–655 |

≥275 |

24 |

20 |

−101 |

|

9% Nickel Steel |

— |

— |

LC9 (9% Ni) |

≥585 |

≥515 |

20 |

27 |

−196 |

|

Austenitic Stainless Steel |

ASTM A351 |

— |

CF8 |

≥485 |

≥205 |

35 |

— |

−254 |

|

18-8 Austenitic Stainless Steel |

ASTM A351 |

— |

CF8M |

≥485 |

≥205 |

30 |

— |

|

The 18Cr–8Ni series of austenitic stainless steels is widely used for ultra-low-temperature valves. Valves operating between −101 °C and −29 °C are generally classified as low-temperature valves, whereas those operating at −101 °C or lower are considered ultra-low-temperature valves. Due to their face-centered cubic (FCC) crystal structure, austenitic stainless steels exhibit stable, isotropic properties and maintain excellent performance at low temperatures, including high toughness, good weldability, and ease of fabrication. Austenitic stainless steel castings for low-temperature valves are typically produced and qualified in accordance with ASTM A351 or JB/T 7248 standards. However, austenitic stainless steels exhibit several notable limitations under cryogenic conditions, as outlined below.

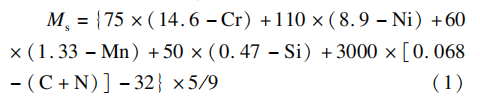

(1) The γ phase of 18Cr–8Ni austenitic stainless steels is metastable. When the temperature drops below the martensitic start temperature (Ms), a martensitic phase transformation occurs. The Ms values for several austenitic stainless steels, calculated using the empirical formula in Equation (1), are listed in Table 2.

Because the volume of martensite is larger than that of austenite, cooling below the Ms temperature leads not only to deformation due to thermal expansion and contraction, but also to macroscopic dimensional changes resulting from the low-temperature phase transformation. When components have irregular shapes or uneven wall thicknesses, this effect can cause non-uniform deformation and dimensional instability.

Table 2. Martensitic Transformation Start Temperatures (Ms) of Selected Austenitic Steels at Low Temperatures

|

Material Grade |

CF8 |

CF8M |

CF3 |

CF3M |

Remarks |

|

Martensitic Transformation Start Temperature, Ms (°C) |

−157.3 |

−207.3 |

−22.0 |

−80.4 |

Chemical compositions are chosen close to the upper or lower limit of the specified ranges. |

(2) Austenitic stainless steels have relatively low tensile and yield strengths at room temperature and are prone to creep under prolonged stresses near their yield strength, particularly in fasteners and sealing components. Prolonged loading can result in stress relaxation, potentially causing sealing degradation, leakage, or other types of failure.

(3) Nickel and manganese are essential alloying elements that prevent low-temperature embrittlement and stabilize the austenitic phase. Consequently, materials designed for ultra-low-temperature applications typically contain substantial amounts of Ni and Mn. However, nickel is an expensive alloying element. In countries with limited domestic nickel resources, where large quantities must be imported, the use of nickel-containing steels results in significantly higher material costs.

(4) Austenitic stainless steels contain high concentrations of chromium and nickel. The extraction and processing of chromium- and nickel-bearing ores generally require substantial amounts of strong acids for leaching and separation, leading to complex production processes, higher costs, and considerable environmental impacts. These processes are energy-intensive, generate significant carbon emissions, and incur substantial costs for environmental remediation. With the advancement of global environmental protection initiatives, greater emphasis is being placed on minimizing environmental impact and carbon emissions. Concepts such as “carbon footprint verification” and “carbon reduction” are increasingly being incorporated into regulatory frameworks, necessitating control of carbon emissions across the entire product life cycle, from raw material production to end-of-life disposal. The European Union led the way by issuing the first carbon footprint verification certificate on October 1, 2023, followed by the adoption of carbon tax regulations in several other countries. In response, the steel industry has set a target to reduce carbon emissions per unit of steel production by 90% by 2050 compared with 2022 levels. As a result, selecting environmentally friendly, low-carbon materials has become a key priority for the equipment manufacturing sector.

Owing to its high strength and outstanding low-temperature performance, 9% Ni steel has become a primary material for constructing cryogenic storage tanks, especially those used for LNG. The development of 9% Ni steel originated in the research laboratories of the International Nickel Company (INCO) in the United States, and the material is qualified for service at temperatures as low as −196 °C. The first 9% Ni steel storage tank was commissioned in the United States in 1952. In 1980, China imported seven spherical storage tanks made of 9% Ni steel from France, each with a capacity of 1.0 × 10³ m³, marking the initial implementation of LNG facilities in China in the late 1980s. In 2004, China commissioned its first large-scale cryogenic liquefied gas project, the Guangdong LNG Project, which featured three storage tanks, each with a capacity of 1.6 × 10³ m³. Since then, major energy companies such as PetroChina, Sinopec, and CNOOC have built—or are currently constructing—more than 20 large-scale LNG storage tanks. Thanks to its excellent weldability and superior low-temperature toughness, 9% Ni steel has become one of the most widely used materials in the manufacture of cryogenic equipment worldwide. Meanwhile, China has gradually achieved domestic production of 9% Ni steel.

Since 2008, with the support of the National Development and Reform Commission and other government agencies, domestic steel producers such as Ansteel, Nanjing Iron and Steel, and Taiyuan Iron and Steel have successfully developed domestically produced 9% Ni steel, ending long-term reliance on imports and significantly accelerating the growth of China’s LNG industry. The low-temperature mechanical properties of 9% Ni steel are largely determined by its chemical composition, especially the carbon and nickel content. In addition, the low-temperature toughness of the steel is highly dependent on its purity and microstructural characteristics. A lower carbon content (C ≤ 0.08%) suppresses carbide precipitation in martensite during tempering, thereby enhancing low-temperature toughness and reducing susceptibility to pitting corrosion. Conversely, excessive carbon content significantly impairs weldability and increases susceptibility to cold brittleness. Nickel addition enhances the matrix's cross-slip capability, reduces the interaction between interstitial atoms and dislocations, lowers the Ac₁ temperature, refines the grain structure, and decreases the ductile–brittle transition temperature, thereby markedly improving low-temperature toughness. To ensure reliable performance at −196 °C, sulfur and phosphorus contents must be strictly minimized to prevent the formation of brittle phases. At the same time, manganese and nickel contents are generally maintained near their upper specification limits, while other alloying elements are strictly limited. These stringent compositional requirements greatly increase both the complexity of steelmaking and the associated production costs. For cryogenic valve applications, 9% Ni steel castings are typically produced and certified in accordance with ASTM A352 LC9 or JB/T 7248 LC9. The material exhibits the following mechanical properties: yield strength ReL ≥ 515 MPa, tensile strength Rm = 585–655 MPa, elongation A ≥ 20%, and impact energy KV ≥ 27 J at −196 °C. The mechanical performance of 9% Ni steel castings is markedly superior to that of 18Cr–8Ni austenitic stainless steels, with a yield strength approximately 2.5 times higher than that of CF8/CF8M grades. This effectively addresses the long-standing issues of low strength and susceptibility to tensile deformation that austenitic stainless steels exhibit in cryogenic service. Meanwhile, the excellent low-temperature toughness of 9% Ni steel castings is a key factor behind their widespread use in cryogenic applications. After nearly a decade of sustained effort, China has successfully localized and industrialized 9% Ni steel, encompassing the systematic development of pipes, flanges, fasteners, welding consumables, valves, equipment, and the associated process technologies. Welding materials and procedures have also been successfully developed and validated. However, the main factors limiting the full replacement of Ni–Cr austenitic stainless steels in practical applications remain the challenges in controlling 9% Ni steel production quality and its relatively high cost, which reduce user willingness to adopt the material on a large scale.

Ultra-low-temperature equipment and systems continue to demonstrate strong development potential. With the gradual engineering application of high-manganese steel LNG storage tanks in LNG carriers, the need for research and application of high-manganese steel casting materials for cryogenic valves has become increasingly apparent. Based on a systematic analysis of the low-temperature performance and engineering application characteristics of 18Cr–8Ni austenitic stainless steel and 9% Ni high-nickel steel, this study focuses on the service conditions of cryogenic valves and investigates the material design and performance verification of high-manganese austenitic cast steel for such applications.

The main conclusions are as follows:

(1) Pressure-bearing materials for cryogenic valves must maintain stable impact toughness at ultra-low temperatures and exhibit high lateral expansion and tensile elongation to meet safety and reliability requirements.

(2) The resistance of materials to plastic deformation under cryogenic conditions significantly affects the sealing performance and operational reliability of valve moving components. The 18Cr–8Ni austenitic stainless steels are prone to martensitic phase transformation at low temperatures, which can lead to additional deformation. Therefore, their structural suitability and compatibility with specific service conditions must be carefully evaluated in engineering applications.

(3) Although 9% Ni steel exhibits excellent mechanical properties and outstanding low-temperature impact toughness, its application requires strict control over chemical composition, smelting purity, and welding procedures. These stringent requirements lead to relatively high material preparation and engineering costs, which limit its broader application in cryogenic valve systems.

(4) This study demonstrates that the high-manganese austenitic cast steel ZG45Mn24C14CuDR, developed for cryogenic valve applications, exhibits high strength, excellent low-temperature impact toughness, and good weldability. By adopting an alloy design strategy that partially replaces nickel with manganese, the material substantially reduces production costs and reliance on nickel resources while fully meeting performance requirements for ultra-low-temperature service. This material aligns with the trends toward low-carbon, green manufacturing and demonstrates strong potential for future engineering applications.

Previous: Research on the Manufacturing Process of Cryogenic Valves

Next: Austenitic High-Manganese Steel for Cryogenic Valves