Austenitic High-Manganese Steel for Cryogenic Valves

Feb 16, 2026

Research on high-manganese austenitic steel for cryogenic valves began relatively early, with reported applications dating back to the 1970s and 1980s. However, owing to limitations in metallurgical technology and process control at that time, its widespread adoption was constrained. With continuous advancements in processing technologies and increasing pressure from energy costs, reducing equipment manufacturing costs has become a critical focus. In the field of ultra-low-temperature containers and storage tanks, several new materials offering high strength, low cost, and excellent low-temperature toughness have been successfully developed and applied, among which high-manganese austenitic steel stands out as a particularly promising solution. In 2017, the United States issued ASTM A1106, High-Manganese Austenitic Steel Plate for Ultra-Low-Temperature Storage Tanks, which specifies the manufacturing and acceptance criteria for high-manganese austenitic steel plates used in cryogenic storage tanks. In 2022, Daewoo Shipbuilding & Marine Engineering and POSCO of South Korea successfully installed LNG fuel tanks fabricated from high-manganese steel on a very large crude carrier (VLCC), representing the world’s first application of high-manganese steel in LNG fuel tanks. This achievement involved the development of comprehensive tank manufacturing technologies, from surface pretreatment to welding, significantly reducing LNG shipbuilding costs and enhancing the competitiveness of South Korean shipyards in the LNG-powered vessel industry. In China, publicly available information indicates that Wuyang Iron and Steel Co., Ltd. conducted trial production of high-manganese steel plates for cryogenic containers in 2019 and successfully obtained acceptance and certification from the China Classification Society (CCS). In 2023, GB/T 713-2023 introduced GB/T 713.5-2023, Steel Plates and Strips for Pressure Equipment—Part 5: High-Manganese Steel with Specified Low-Temperature Properties, which specifies the production and acceptance criteria for 45Mn24Cr4CuDR austenitic high-manganese steel plates used in cryogenic containers.

Meanwhile, systematic research on welding methods and procedures for ultra-low-temperature high-manganese steel has been carried out, yielding significant progress in the development of welding techniques and filler materials for both manual arc welding and gas-shielded welding. Regarding cryogenic valve castings—which serve as essential complementary components to cryogenic containers and pipelines—no publicly reported applications of high-manganese steel have been documented to date, either domestically or internationally. Based on the design requirements for cryogenic materials and in comparison with currently used cryogenic steels, collaborative research and casting trial production of austenitic high-manganese steel for cryogenic valve applications (hereinafter referred to as high-manganese steel) were carried out. Phased results demonstrating favorable low-temperature performance have been obtained, as shown in Figure 1. In accordance with the relevant provisions of ASTM A1106-2017 and GB/T 713.5-2023, systematic investigations and trial production were conducted, focusing on the relationship between alloy composition and strength, heat-treatment strategies for grain refinement and toughness optimization, and improvements in inclusion control and casting processes. In addition, breakthroughs were achieved in welding technology and in the cryogenic performance verification of valves, alongside successful industrial trial production.

Grain size has a significant effect on the strength and low-temperature impact toughness of metallic materials, and grain refinement is an effective approach for enhancing material strength. Appropriate additions of alloying elements, such as aluminum (Al) and vanadium (V), can promote grain refinement and enhance austenite stability. However, excessive aluminum (Al) content tends to promote grain growth and coarsening, while excessive vanadium (V) content can negatively impact weldability.

Comparative analysis indicates that increasing the aluminum (Al) content to 0.10% and the vanadium (V) content to 0.15% in the chemical composition of high-manganese steel can raise the yield strength by approximately 30 MPa, while the impact energy at −196 °C can be increased by about 20 J.

Figure 1. As-cast austenitic high-manganese steel ZG45Mn24Cr4CuDR casting

From a casting-process perspective, high-manganese steel is characterized by a high manganese content and relatively low molten-steel fluidity. To improve fluidity, high-temperature pouring is employed. However, this process generates intense fumes and promotes severe oxidation, which can readily result in slag inclusion defects. To mitigate oxidation and shield the molten steel from atmospheric exposure, deoxidizers are added to its surface in the ladle. In addition, molding sand and facing sand with high permeability and refractoriness are used to reduce sand adhesion on the casting surface, thereby minimizing internal inclusion defects in high-manganese steel castings.

The as-cast high-manganese steel exhibits a coarse carbon-manganese, fully austenitic structure with low yield strength. Grain refinement is necessary to enhance both the tensile and yield strengths of the material. Since all low-temperature high-manganese steel alloy systems exhibit an aging embrittlement range, heat treatment at 500–900 °C to obtain a recrystallized fine-grained structure results in a significant decrease in the material’s ultra-low-temperature impact absorption energy compared to the as-cast state. Above 900 °C, low-temperature toughness improves, although the increase is minimal beyond 1000 °C. Based on the comparison of strength and low-temperature impact toughness data after solution treatment at various temperatures, and considering the economic aspects of heat treatment, it is concluded that high-manganese steel subjected to solution treatment at 1050 °C achieves the optimal combination of strength and toughness. The tested ultra-low-temperature high-manganese steel valve casting exhibits a tensile strength of 700 MPa, a yield strength of 340 MPa, an elongation after fracture of 70%, and an average V-notch low-temperature impact energy of 160 J at −196 °C, with a lateral expansion (LE) of 1.9 mm.

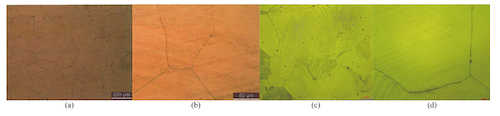

Microstructural examination using a 4XC metallographic microscope (YSJX-02) at 100× and 400× magnification revealed a fully austenitic structure with a small amount of point-like and short-line carbides distributed along the grain boundaries (Figure 2).

(a) 980°C solution treatment/100x magnification (b) 980 Solution Treatment/400x Magnification (c) 1050 Solution Treatment/100x Magnification (b) 1050 Solution Treatment/400x Magnification

Figure 2 Metallographic analysis of the fabricated austenitic high-manganese steel ZG45Mn24Cr4CuDR

Regarding welding, butt welding process qualification was performed in accordance with ASME Section IX for both homogeneous (same-material) and dissimilar (with F316L) welds. Samples were extracted from the weld, heat-affected zone, and base metal for tensile testing, side-bend testing, −196 °C low-temperature impact toughness evaluation, hardness measurement, and metallographic analysis. The maximum crack observed in the side-bend test of the homogeneous weld was 0.6 mm, whereas no cracks were detected in the dissimilar weld. Additional test data are presented in Table 3. All test results met the specified requirements. Both butt-weld samples exhibited no defects in macroscopic metallography. The weld microstructure was fully austenitic, with a small amount of carbides dispersed within it. Representative metallographic analysis is presented in Figure 3. The as-cast high-manganese steel exhibits a coarse carbon–manganese, fully austenitic microstructure with relatively low yield strength.

Table 3. Welding Procedure Qualification Test Results

|

Welding Type |

Location |

Tensile Strength (MPa) |

Elongation after Fracture (%) |

Impact Energy at −196 °C (J) |

Lateral Expansion (mm) |

Hardness (HV10) |

|

Same Material Butt Weld |

Base Metal |

783, 784, 725, 785 |

— |

168.5, 163.5, 158.0, 121.0 |

1.942, 1.995 |

178–181 |

|

|

Weld Metal |

— |

— |

— |

— |

191–200 |

|

|

Heat-Affected Zone |

— |

— |

— |

1.816 |

191–205 |

|

|

Base Metal (F316L) |

— |

— |

— |

1.231 |

162–173 |

|

Dissimilar Butt Weld (with F316L) |

Base Metal (High-Mn Steel) |

631, 636, 646 |

66.5 |

169.0, 122.5, 161.0, 117.0 |

1.834 |

177–182 |

|

|

Weld Metal |

628 |

59.5, 58.5, 59.5 |

— |

1.721 |

172–192 |

|

|

HAZ (High-Mn Steel Side) |

— |

— |

— |

1.756 |

189–202 |

|

|

HAZ (F316L Side) |

— |

— |

— |

1.134 |

168–176 |

(a) Homogeneous butt weld, 100× (b) Homogeneous butt weld, 400× (c) Dissimilar butt weld, 100× (d) Dissimilar butt weld, 400×

Figure 3 Metallographic analysis of butt welds of austenitic high-manganese steel ZG45Mn24Cr4CuDR

Table 4 presents the measured mechanical properties of the fabricated cast austenitic high-manganese steel ZG45Mn24Cr4CuDR, alongside those of stainless steel castings ASTM A351 CF8, ASTM A351 CF8M, and ASTM A352 LC9. The comparison indicates that the cast austenitic high-manganese steel ZG45Mn24Cr4CuDR exhibits excellent mechanical properties and outstanding low-temperature toughness. Welding procedure qualification tests further confirm its excellent weldability, demonstrating that the material meets the requirements for industrial applications. Metallographic analysis indicates that ZG45Mn24Cr4CuDR has a fully austenitic microstructure, with no martensitic transformation observed at low temperatures. As a result, deformation caused by thermal expansion and contraction under cryogenic conditions is relatively small. This behavior is beneficial for maintaining reliable sealing performance in cryogenic valves and for ensuring the dimensional stability of moving components exposed to large temperature gradients. In terms of corrosion resistance, the oxidation and overall corrosion performance of high-manganese steel is comparable to that of ASTM A352 LC9 (9% Ni) steel, and is sufficient to meet the requirements for low-temperature dry media.

Table 4. Comparison of Measured Mechanical Properties of Materials

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Impact Energy at −196 °C (J) |

Lateral Expansion (mm) |

Elongation (%) |

|

ZG45Mn24Cr4CuDR |

700 |

340 |

160 |

1.9 |

70.0 |

|

ASTM A351 CF8 |

535 |

260 |

9 |

0.9 |

43.5 |

|

ASTM A351 CF8M |

549 |

265 |

80 |

1.5 |

45.5 |

|

ASTM A352 LC9 |

625 |

540 |

63 |

0.8 |

39.0 |

From a material economics perspective, data from the Korea Institute of Industrial Technology Evaluation indicate that, compared with aluminum alloys, high-manganese steel has a unit price of only 53%, a welding cost of 9%, a material consumption of 167%, and a total cost of just 56%. Compared with 9% Ni steel, high-manganese steel is roughly four times more cost-effective. Further comparison with high-nickel alloy steel (9% Ni) and 18-8 austenitic stainless steel, both widely used in ultra-low-temperature equipment and storage tanks, shows that the unit price of high-manganese steel is 46% that of 9% Ni steel, the welding cost is only 6.8%, and the total manufacturing cost is 27% of 9% Ni steel and 44% of SUS304 stainless steel. These results underscore the significant economic advantages of high-manganese steel for cryogenic applications.

Through rational alloy design, precise control of the casting process, and optimization of solid-solution heat treatment, the developed high-manganese austenitic cast steel retains a fully austenitic microstructure at −196 °C. It demonstrates high strength, excellent low-temperature impact toughness, and good plastic deformation capacity. Moreover, the welded joints meet engineering application requirements in terms of low-temperature mechanical performance, structural stability, and defect control. Compared with conventional 18-8 austenitic stainless steel and 9% Ni steel, the proposed material substantially reduces reliance on nickel resources while ensuring reliable performance under ultra-low-temperature service conditions, thereby offering a clear advantage in overall manufacturing cost. In summary, the newly developed ultra-low-temperature austenitic high-manganese cast steel ZG45Mn24Cr4CuDR demonstrates outstanding overall performance in mechanical properties, low-temperature toughness, weldability, and cost-effectiveness. It offers a promising new technical pathway for material selection in cryogenic valve applications and holds significant practical value in promoting the localization and cost reduction of low-temperature valves and associated equipment.

Previous: Development of Low-Temperature High-Manganese Steel for Cryogenic Valves