Current Status and Challenges in Seat Sealing for LNG Top-Entry Cryogenic Trunnion Ball Valves

Dec 11, 2025

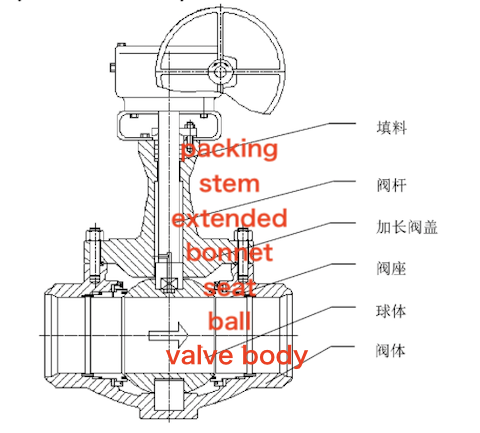

With the early development of the LNG industry overseas, cryogenic ball valve designs from well-known international manufacturers such as Poyam, Cameron, Velan, and Valvitalia have become relatively mature, featuring stable structures and reliable performance. However, these manufacturers generally employ single-seat, unidirectional (single-piston) designs with either fixed or floating ball structures. Some manufacturers also use split-body valve designs, which do not support online maintenance. In addition, the sealing performance of configurations transitioning from single-seat, unidirectional (single-piston) to single-seat, bidirectional (double-piston) designs is constrained by the standardized dimensions of Lipseal rings and by limitations in product adaptability. In LNG projects developed by CNPC and Sinopec, Poyam products are the most commonly chosen. A typical top-entry cryogenic ball valve structure from Poyam is shown in Figure 1.3.

Figure 1.3 Structure Diagram of Poyam Top-Entry Cryogenic Ball Valve

Analysis of Poyam’s products indicates that the external leakage points are not sealed with Lipseal rings; the body–cover joint employs a metal-ring gasket, and the valve stem is sealed with GRAPHOLL packing. The upstream valve seat includes an opening for cavity pressure balance, indicating that the valve employs an outlet-end sealing configuration. However, the valve seat is not spring-loaded and is instead mechanically secured with threads to press it against the ball. Although this arrangement can achieve an initial mechanically induced seal, it does not provide compensation for long-term wear of the valve seat. Overall, Poyam’s top-entry LNG cryogenic fixed ball valves do not completely address the following issues:

(1) They fail to fully satisfy the low-leakage and durability testing requirements outlined in ISO 15848.

(2) The valve seat lacks a rear spring preload, and the upstream seat features an opening.

As a result, a combination valve seat—comprising a single-seat one-way (single-piston) and a single-seat two-way (double-piston) design—capable of achieving full DIB-2 functionality has not yet been realized. This issue was verified through on-site inspection at the Shandong LNG terminal.

(3) There is no bearing between the valve stem and the valve body. The ball is supported by a shoulder at the lower end of the stem, which makes the stem prone to bending during operation.

Domestically, many manufacturers claim the capability to produce cryogenic valves; however, they generally fall into three categories:

1) Manufacturers that have never produced cryogenic valves, relying on design methods intended for ambient-temperature valves, and in some cases lacking the necessary cryogenic valve manufacturing license.

2) OEM-oriented manufacturers that produce cryogenic valves for domestic or international brands. These companies possess a basic understanding of cryogenic valve design but often still face limitations related to manufacturing qualifications.

3) Manufacturers with established technology and capabilities for cryogenic valve production, serving as the backbone enterprises of China’s cryogenic valve industry.

In fact, the domestic LNG industry developed relatively late, and until recent years, most Chinese valve manufacturers focused primarily on cryogenic valves for air separation units. Valves designed for the ultra-low-temperature and high-reliability requirements of LNG applications were few in number, relatively simple in design, and lacked long-term performance stability. Given these challenges, along with cost constraints and recent LNG market conditions, most domestic manufacturers have adopted the following strategies in designing cryogenic ball valves:

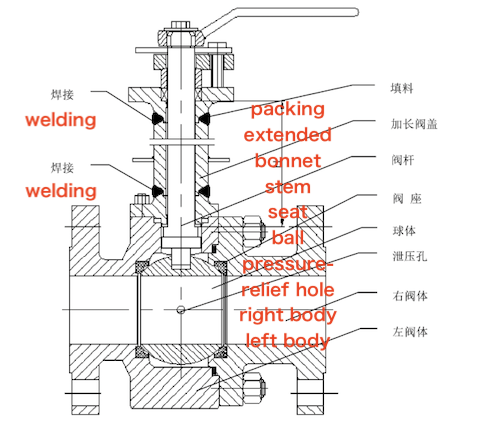

(1) In order to eliminate the need for Lipseal sealing rings, manufacturers typically select split-type, side-mounted floating ball valve structures, which simultaneously lowers the difficulty of valve manufacturing. For the extended bonnet, a segmented welded construction is used to reduce both cost and machining complexity. The structure of a side-mounted cryogenic floating ball valve is shown in Figure 1.4.

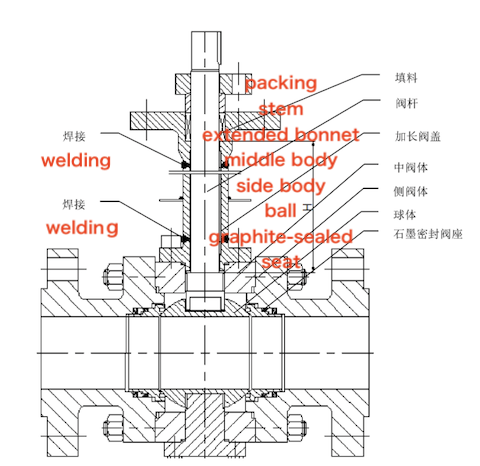

(2) Similar to high-temperature ball valves, graphite is used as the sealing material between the seat and the valve body in fixed cryogenic ball valves to avoid the use of Lipseal seals. Split-body designs and segmented welded extended bonnets also help reduce manufacturing complexity and cost. The structure of a side-mounted cryogenic fixed ball valve is shown in Figure 1.5.

(3) For seat cavity pressure relief, floating ball valves rely on an opening on the high-pressure side of the ball.

(4) A downstream dual-piston function cannot be achieved.

(5) For external leakage control, metal–graphite spiral-wound gaskets are used to avoid the application of Lipseal rings and to reduce overall costs.

Overall, such products are suitable for air-separation units operating at temperatures above –100 °C. However, compared with the requirements of LNG service, their performance still shows significant gaps. These products are suitable for temperatures above –100 °C; however, compared with LNG service conditions, significant performance gaps remain. For example, they include numerous potential external leakage points, and graphite sealing materials cannot provide the required sealing performance for LNG applications. Graphite powder tends to shed, valve torque is relatively high, and the valves do not support online maintenance. In recent years, many domestic manufacturers have made continuous efforts to advance LNG cryogenic valve technology, focusing primarily on the following areas:

Figure 1.4 Structural diagram of a side-mounted cryogenic floating ball valve

(1) The adoption of top-entry designs has enabled online maintenance and has encouraged domestic manufacturers to further explore ways to improve maintenance convenience.

(2) The use of Lipseal sealing rings has facilitated the adoption of new sealing technologies, while the introduction of Hawker mirror-finishing equipment has enhanced machining precision.

(3) The introduction and investigation of dual-material piping concepts have advanced the development of new materials within the domestic valve industry.

These efforts have partially advanced the localization of LNG ball valves, but overall progress has been relatively slow. Domestic manufacturers remain relatively inexperienced in applying ball valve technologies under LNG cryogenic conditions. The combined seat design, which integrates single-seat unidirectional (single-piston) and single-seat bidirectional (double-piston) functions to meet DIB-2 requirements, still lacks practical experience—especially in machining the Lipseal seat’s inner bore and controlling Lipseal compression and stop features. Consequently, the actual performance in the field remains unsatisfactory. For online maintenance, most manufacturers still use retaining-ring structures or direct-contact threaded seat designs, which are difficult to disassemble and prone to causing valve seat damage. The pass rate for type testing under ISO 15848 low-leakage standards remains low, and the adoption of this technology is still very limited.

Figure 1.5 Structural diagram of a side-entry cryogenic fixed ball valve

Overall, the main bottlenecks include inadequate machining accuracy and the large spring forces required in online-maintenance seat structures, which result in high disassembly and assembly forces; retaining-ring seat designs that require special tooling, which reduces maintenance convenience; and a lack of adequate research methods for assessing material deformation under cryogenic conditions. These factors have greatly hindered the localization of LNG top-entry cryogenic ball valves. However, over the past two years, LNG development has accelerated, driven by increasing national focus on environmental protection and new energy initiatives. China is actively advancing LNG projects across Guangdong, Fujian, Zhejiang, Shanghai, Jiangsu, Shandong, Liaoning, Ningxia, Tangshan, and Hebei, aiming to establish an integrated coastal LNG receiving and transmission pipeline. The rapid expansion of LNG, coupled with strong national support for “domestic products replacing imports,” has created significant opportunities for the localization of LNG top-entry cryogenic ball valves. Guided by the National Development and Reform Commission and the National Energy Administration, and supported by end-users such as CNPC, Sinopec, and CNOOC, with technical guidance from leading design institutes including Luoyang Design Institute and SEI, domestic manufacturers have demonstrated strong commitment to developing LNG top-entry cryogenic ball valves. Currently, several Chinese companies are actively and continuously pursuing this development.

This study focuses on the seat sealing system of LNG top-entry cryogenic fixed (trunnion-mounted) ball valves. Based on the design requirements for top-entry trunnion ball valves in LNG service, this research focuses on seat structure, sealing performance, and sealing materials, providing technical guidance for the localization of LNG ball valves.

The main research tasks include:

• Structural design and analytical calculations for LNG top-entry cryogenic trunnion ball valves;

• Analysis and evaluation of seat sealing materials suitable for LNG top-entry cryogenic trunnion ball valves;

• Analysis of online maintenance structures for LNG top-entry cryogenic trunnion ball valves;

• In-depth study of seat sealing performance, covering seat geometry, fastening methods for non-metallic seats, implementation of the dual-piston function, and design of the Lipseal sealing-ring structure.

The key technical challenges addressed in this study are as follows:

(1) Achieving reliable sealing in single- and dual-piston seat designs

LNG top-entry trunnion ball valves require a transition from single-seat unidirectional (single-piston) sealing to single-seat bidirectional (double-piston) sealing. At cryogenic temperatures, the hardness of non-metallic seat materials increases, placing greater demands on the sealing interface between the ball and seat, as well as on the integrity of the non-metallic seat within its groove.

Therefore, the design must implement a well-conceived sealing structure grounded in sealing principles, with clearly defined requirements for sealing surface finish and geometry, to ensure reliable seat performance.

(2) Challenges in applying Lipseal sealing rings for cryogenic dual-piston seats

A Lipseal lip-type sealing ring is required between the valve seat and the body to achieve effective sealing under cryogenic conditions. However, the use of Lipseal rings in dual-piston seat designs is limited by:

- inconsistencies in size series among different Lipseal manufacturers

- very stringent requirements for the machining accuracy of the sealing surfaces

Accordingly, the valve design must adopt a rational structural layout and dimensional scheme that satisfies both the sealing requirements and the practical manufacturing capabilities of Lipseal suppliers to achieve the desired sealing performance.

This study analyzes and compares several representative online-maintenance structures, proposes a practical and reliable design for seat online maintenance, and conducts verification and optimization. The goal is to improve the convenience and safety of online maintenance while maintaining structural integrity and reliable sealing performance.

Overall, domestically manufactured LNG top-entry cryogenic fixed ball valves continue to encounter significant technical challenges, particularly in machining precision, seat sealing reliability, dual-piston functionality, and the design of online maintenance systems. On the one hand, domestic manufacturers have limited experience with seat machining accuracy, Lipseal installation, and sealing-surface control, which can result in potential leakage risks during prolonged cryogenic operation. On the other hand, current online-maintenance designs are cumbersome to disassemble and reassemble, and the methods used to fasten the seat to the body provide insufficient compensation for wear during long-term operation, limiting both the convenience and reliability of valve maintenance. Furthermore, the altered mechanical properties of materials at cryogenic temperatures, the increased hardness of non-metallic seats, and the susceptibility of valve stems to bending impose greater demands on the valve’s overall sealing integrity and operational performance. Given the rapid expansion of China’s LNG industry and the national push for “domestic substitution of imports,” the urgency for strengthening domestic R&D capabilities has become increasingly evident. This study centers on the seat-sealing technology of LNG top-entry cryogenic trunnion ball valves, carrying out systematic research on seat-structure design optimization, non-metallic seat material evaluation, implementation of dual-piston functionality, and the development of the Lipseal sealing-ring structure. It also optimizes and verifies the performance of the online-maintenance structure. Through modular design, finite-element analysis, 3D simulation, cryogenic testing, and iterative prototype optimization, the study achieves significant improvements in seat-sealing reliability, operating-torque control, and the overall ease of online maintenance. This research provides a systematic design methodology and a solid technical foundation for the development of domestically produced LNG top-entry cryogenic trunnion ball valves. It not only provides robust theoretical and practical data for optimizing valve sealing and operational performance, but also offers valuable guidance for valve localization, reliable field operation, and maintainability in domestic engineering applications, thereby contributing to the advancement of China’s LNG top-loading cryogenic ball valve technology.

Previous: LNG Cryogenic Top-Entry Trunnion Ball Valves: Seat Sealing Design and Performance Study

Next: Cryogenic Instrument Valve Design for LNG Receiving Terminals