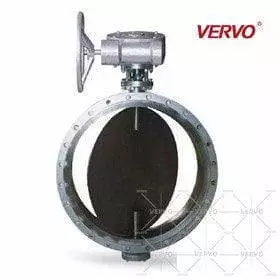

API 609 Butterfly Valves

API 609 Butterfly Valves are quarter-turn flow control and isolation valves widely used in pipeline systems and pressure vessels across the petroleum, natural gas, petrochemical, power generation, and related industries. Designed and manufactured in full compliance with API 609 standards, these valves ensure reliable performance, structural integrity, and operational safety under demanding service conditions.

In all cases where the Official API Monogram is applied, it is used in conjunction with API Certificate Number 609-0341, confirming that the valve design, materials, manufacturing, and testing processes meet stringent API requirements. API 609 butterfly valves are classified under Category A, which defines performance criteria for resilient-seated butterfly valves commonly used for on-off and throttling applications.

The API 609 standard emphasizes comprehensive performance validation. Valve designs are verified through prototype testing, ensuring structural strength and operational reliability. Materials are carefully selected to withstand specific temperature and pressure ratings, while strict seat leakage tests guarantee tight shut-off performance. Additionally, cycle life testing is conducted to verify durability over a specified number of open-close operations. Mandatory positive isolation testing confirms that the valve can effectively prevent leakage, reducing risks such as fugitive emissions in oil and gas pipeline networks.

API 609 also clearly defines the design and manufacturing requirements for butterfly valves, including connection types, structural configurations, and face-to-face (FTF) dimensions. Multiple connection forms are available to suit various installation needs, including wafer, lug, double-flanged, grooved, and welded butterfly valves. These options provide flexibility for different pipeline systems and operating environments.

In terms of structural design, API 609 butterfly valves are available in centerline (concentric) and eccentric configurations, including double eccentric and triple eccentric butterfly valves. Eccentric designs reduce seat wear, improve sealing performance, and extend service life, making them ideal for higher pressure and temperature applications.

The standard also specifies face-to-face dimensions, divided into Series A and Series B. Series A generally applies to wafer and lug-type valves, while Series B covers wafer, lug, and flanged types. Flanged butterfly valves are further categorized into long-pattern and short-pattern structures, allowing compatibility with different piping standards and installation requirements.

As a leading API 609 butterfly valve manufacturer in China, we supply a comprehensive range of high-quality butterfly valves with strict quality control, advanced manufacturing technology, and full compliance with international standards. Our API 609 butterfly valves are trusted by global customers for their high flow capacity, reliable sealing, long service life, and safe operation in critical industrial applications.