Optimized Design and Performance of Electric Gate Valves for Nuclear Power Plants

Sep 09, 2025

Abstract: To address frequent sealing failures and slow actuation of electric gate valves in nuclear power plants, a remote structural and performance optimization approach is proposed. A dual-pass sealing structure is employed to reduce seal wear, permanent magnet synchronous servo drive technology is applied to enhance response speed, and finite element analysis is used to optimize the stress distribution of the valve body. In addition, models for seal performance degradation and actuation characteristics are established to enable quantitative design of key parameters. Engineering verification demonstrates that the optimized solution significantly improves equipment reliability and operational performance, providing a valuable technical reference for the design of critical nuclear power equipment. With the rapid advancement of nuclear power technology, performance requirements for critical equipment in nuclear power plants continue to increase. Electric gate valves, as essential fluid control components, directly influence the safe and stable operation of nuclear power units. However, existing electric gate valves often experience rapid seal degradation, slow actuation, and limited control accuracy in practical applications. Addressing these challenges through remote design and performance optimization of electric gate valves is therefore of critical engineering importance and provides significant value in enhancing both the operational safety and economic efficiency of nuclear power plants.

1. Analysis of Current Issues and Performance Requirements for Electric Gate Valves in Nuclear Power Plants

As essential nuclear safety equipment, electric gate valves in nuclear power plants encounter numerous technical challenges during long-term operation due to complex operating conditions and harsh environments. The valve’s sealing structure exhibits a short service life under high-temperature, high-pressure, and corrosive conditions, with field data indicating that the seal lasts only 65% of its designed lifespan. The actuator is influenced by temperature variations and mechanical stress, leading to reduced operational stability and reliability. The response time fluctuates by more than 1.5 seconds across a temperature range of –40 °C to 200 °C, and operating accuracy varies by ±2.5 mm. The control system exhibits low precision in valve position and torque regulation, causing issues such as valve jamming and delays during hot–cold transitions. The valve body design additionally exhibits stress concentration, accelerating material fatigue, equipment aging, and increasing the risk of leakage. To meet the requirements of next-generation nuclear power units, the sealing performance degradation of electric gate valves should remain below 10% over a 40-year service life. The actuator response time must be kept under 1 second, operating accuracy should be better than ±0.5 mm, torque control precision must exceed 0.5 N·m, and valve position control accuracy should be greater than 0.1 mm. Furthermore, the uniformity of valve body stress distribution should be increased by over 30%, and the material fatigue life should be extended to 60 years.

The remote structural design of electric gate valves focuses on two key components: the valve body and its sealing structure, and the drive mechanism. By optimizing the valve body’s stress distribution and enhancing the sealing structure, the sealing performance is improved and service life extended. Simultaneously, a newly developed drive mechanism provides fast and precise motion control, meeting the stringent operational requirements of nuclear power plants.

The electric gate valve body features an integral design, comprising primarily the electric actuator and the valve body. For the design of nuclear power valve sealing surfaces, the sealing surface contact stress, σ, is a critical parameter and is calculated as follows:

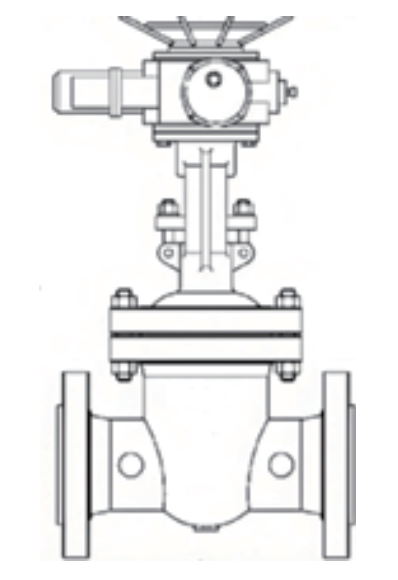

Where: F is the sealing pressure (N); Di is the inner diameter of the seal ring (mm); Do is the outer diameter of the seal ring (mm); and b is the contact width of the sealing surface (mm). The top of the valve body features an electric actuator support structure, optimized for strength and rigidity using finite element analysis (FEA) to ensure efficient transmission of driving torque (Figure 1). A guide groove mechanism within the valve body governs the disc’s movement, while a precision-machined sealing surface combined with an elastic sealing ring provides dual sealing. The valve cavity has been optimized using computational fluid dynamics (CFD) to reduce local flow resistance and enhance flow capacity. The sealing system features a dual-pass design: the primary sealing surface is plasma-sprayed with carbide, and its contact stress distribution has been optimized using finite element analysis (FEA). For the sealing materials, the primary surface uses the cobalt-based alloy Stellite 6, with a surface hardness exceeding 45 HRC. The secondary seal consists of modified flexible graphite with a purity exceeding 99.9% and a compression rebound strength above 98%, ensuring excellent reliability and long-term durability.

Figure 1. Electric Gate Valve Body Structure

The remote drive mechanism is designed to improve operational stability and reliability, utilizing a modular approach and optimized transmission and motor control systems. The transmission mechanism incorporates a novel dual-lead screw design with an optimized lead angle of 12°, substantially reducing self-locking friction. The bearing system combines angular contact and thrust ball bearings to enhance axial load capacity and operational precision. The motor system uses a permanent magnet synchronous servo motor equipped with a high-precision encoder, increasing torque density by 40% and achieving a control accuracy of 0.1°. Dynamic simulation of the entire drive mechanism optimizes inertia matching among key transmission components, minimizing startup shock and vibration while ensuring rapid, stable, and smooth operation.

The performance optimization of electric gate valves in nuclear power plants focuses on improving reliability and stability under high-temperature and high-pressure operating conditions. The optimization objectives include extending the long-term stability of sealing performance to 150% of the original design life, reducing valve actuation response time to 0.8 s, improving actuation accuracy to ±0.1 mm, and ensuring torque adjustment accuracy better than 0.5 N·m, with valve position adjustment accuracy of ±0.05 mm. A comprehensive optimization plan was developed, encompassing sealing system upgrades, drive mechanism performance enhancements, and control system improvements. A multi-parameter coupling analysis method was applied to establish a correlation model between sealing performance and drive characteristics. Based on the performance targets, optimization was carried out along three axes:

Sealing performance optimization: Enhancing the reliability and service life of the sealing structure.

Operating characteristics optimization: Improving stability and accuracy during valve opening and closing.

Control system optimization: Upgrading response speed and control precision.

Together, these three interdependent optimization areas form a holistic solution for enhancing the overall performance of electric gate valves.

Sealing performance optimization is based on the wear rate theory of the sealing pair. The wear rate W is expressed as:

![]()

Where: K is the wear coefficient, determined by material properties and operating conditions; P is the contact pressure of the sealing surface (MPa); v is the relative sliding velocity (m/s); and t is the operating time (h). Optimization measures include refining the sealing structure, enhancing the micro-topography of the sealing surface, and applying plasma surface treatment to improve hardness and wear resistance. The stuffing box structure is optimized with an elastic compensation device to prevent sealing failures caused by temperature fluctuations. A composite sealing structure is used, incorporating a dustproof ring around the primary seal to extend the service life. Additionally, high-precision CNC machining is employed to enhance the accuracy of the sealing surface, with a surface roughness (Ra) maintained within 0.4 μm and contour tolerance within 0.01 mm, achieving an optimal sealing structure design.

The optimization of the electric gate valve’s motion characteristics focuses on two key performance indicators: stability during opening and closing, and positioning accuracy. A permanent magnet synchronous servo motor was employed instead of an asynchronous motor to improve starting torque and speed control performance. The transmission mechanism was optimized using a precision-grade dual-lead screw with Grade I pitch accuracy and backlash limited to 0.02 mm. Dynamic modeling was used to analyze the valve’s opening and closing processes and to refine the acceleration and deceleration curves. Bearing support was upgraded with a combination of angular contact and thrust ball bearings, enhancing axial positioning accuracy and stiffness. In addition, a motion characteristic evaluation system was implemented to enable intelligent diagnostics and early warning of abnormal valve motion conditions.

The electric gate valve control system employs a modular design, establishing a complete architecture for both opening control and torque protection. A high-performance 32-bit industrial-grade processor was utilized, reducing the control cycle to 1 ms, while distributed deployment via a fieldbus enhances anti-interference capability. A fuzzy proportional-integral-derivative (PID) control algorithm was implemented, enabling adaptive control of the valve opening process for rapid response and precise positioning. The torque protection module employs a dual-redundancy design with real-time monitoring via high-precision sensors, allowing rapid execution of protective actions. Optimized human–machine interaction, incorporating visual displays and remote monitoring, further improves management efficiency and facilitates maintenance.

Verification experiments for the optimized design scheme were carried out using a nuclear power plant simulated operating condition test bench. The test bench can simulate operating conditions ranging from –40 °C to 350 °C and pressures from 0 to 16 MPa. The experimental design adhered to the standards of Steel Gate Valves with Stud-Connected Bonnets for the Petroleum and Natural Gas Industry (GB/T 12234 2019) and encompassed tests of sealing performance, operating characteristics, and control performance. An orthogonal experimental design method was employed to determine parameter combinations, with tests conducted under three representative operating conditions:

Normal temperature and pressure: (20 ± 5) °C, 0.1 MPa

High temperature and high pressure: (200 ± 10) °C, 16.0 MPa

Hot–cold transition: Simulating startup and shutdown, with temperature cycling from –40 °C to 200 °C and pressure varying from 0.1 to 16.0 MPa

Each set of tests consisted of 5,000 opening and closing cycles per operating condition, with performance parameters continuously recorded using a high-precision data acquisition system. The test data were analyzed using specialized data processing software. To ensure reliability, each experiment was repeated five times. The entire test campaign spanned 3,000 hours, providing a comprehensive record of equipment performance degradation over time. The final results were assessed using the average values obtained from the three operating conditions.

Performance tests of the optimized electric gate valve encompassed evaluations of sealing performance, actuation characteristics, and control accuracy. Table 1 provides a comparison of the valve’s performance before and after optimization.

Sealing performance: The degradation rate of the sealing performance was 8.5%, meeting the requirement of less than 10.0%. The uniformity of stress distribution improved by 38%, exceeding the design target of 30%.

Actuation characteristics: The valve’s response time was 0.75 s, and its actuation accuracy was ±0.3 mm, both exceeding the specified requirements.

Control performance: Torque control accuracy reached 0.3 N·m, and valve position control accuracy reached 0.08 mm, both surpassing the design requirements.

The optimized electric gate valve underwent a one-year engineering verification at a nuclear power plant, operating under three typical conditions: normal temperature and pressure, high temperature and high pressure, and hot–cold transition. Detailed monitoring data are presented in Table 2. The data show that all performance indicators exceeded the design requirements. The sealing performance degradation rate ranged from 2.1% to 3.2%, well below the 10.0% limit. The response time ranged from 0.72 to 0.78 s, meeting the ≤1.00 s requirement. Displacement accuracy was within ±0.50 mm, torque control accuracy ranged from 0.28 to 0.32 N·m—better than the ≤0.50 N·m specification—and system reliability exceeded 99.98%, surpassing the 99.95% design standard. The number of failures per thousand hours ranged from only 0.01 to 0.02, well below the ≤0.05 requirement. These results confirm that the optimized design exhibited excellent stability and reliability under all three operating conditions.

Table 2. One-Year Performance Monitoring Data for Optimized Electric Gate Valves

|

Monitoring Item |

Design Requirement |

Normal Temp. |

High Temp. & Pressure |

Hot–Cold Transition |

|

Seal Performance Degradation Rate (%) |

≤10.0 |

2.1 |

3.2 |

2.8 |

|

Response Time (s) |

≤1.00 |

0.72 |

0.78 |

0.75 |

|

Displacement Accuracy (mm) |

±0.50 |

±0.25 |

±0.30 |

±0.28 |

|

Torque Control Accuracy (N·m) |

≤0.50 |

0.28 |

0.32 |

0.30 |

|

System Reliability (%) |

≥99.95 |

99.99 |

99.98 |

99.99 |

|

Failures per 1000 h |

≤0.05 |

0.01 |

0.02 |

0.01 |

Through remote design and performance optimization, the primary limitations of conventional electric gate valves in nuclear power plants have been effectively overcome. The optimized valves demonstrated substantial improvements in sealing performance, operational stability, and control accuracy, with all performance indicators fully satisfying nuclear safety requirements. Experimental and field results confirm that the enhanced design exhibits excellent engineering applicability and offers valuable technical guidance for optimizing critical equipment in nuclear power plants. This research provides valuable guidance for improving the safety and reliability of nuclear power plant operations.

Previous: L Type Three-Way Ball Valves for Natural Gas Reversing in Glass Melting Furnaces

Next: High-Performance NiCr Corrosion-Resistant Ductile Iron Butterfly Valves