Design and Application of a Pneumatic Quick-Opening Shut-Off Valve

Nov 11, 2025

Abstract: During operation, conventional pneumatic shut-off valves often fail to quickly discharge the gas medium from the upper side of the cylinder piston, resulting in backpressure damping and preventing rapid valve opening. To address this issue, this paper presents the design of a pneumatic quick-opening shut-off valve developed to meet specific operational requirements. The working principle, structural design, and operating process of the valve are described in detail. Its sealing performance and rapid-opening capability are verified through theoretical analysis and calculations, confirming that the proposed structure enables rapid valve actuation. In modern industrial production, fluid control plays a vital role. As essential fluid control devices, pneumatic quick-opening shut-off valves are widely used in the petroleum, chemical, power generation, and metallurgical industries. They feature a fast response and reliable sealing performance, effectively regulating fluid flow and enhancing the safety and stability of industrial processes.

The pneumatic quick-opening shut-off valve ensures efficient and reliable fluid control within pipeline systems through the coordinated operation of its internal components. When the pneumatic actuator receives a control signal, compressed air drives the valve stem to move, opening or closing the valve disc. The sealing surface between the valve disc and the valve body ensures a tight shutoff and prevents fluid leakage. Pneumatic actuators typically use either a piston or diaphragm design, providing rapid response and high output force. Control signals—electrical, pneumatic, or otherwise—are transmitted to the actuator through a control system, enabling remote and automated valve operation.

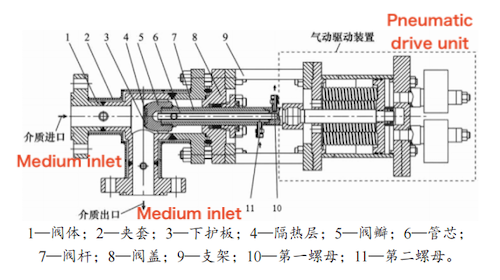

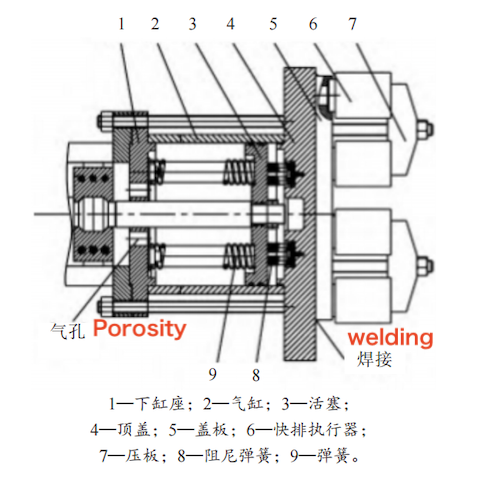

To enable rapid actuation, a pneumatic quick-opening shut-off valve was specifically designed. The valve’s overall structure, shown in Figure 1, consists of two main components: the valve body assembly and the pneumatic drive unit, as illustrated in Figure 2. The valve body assembly primarily consists of the valve body, valve disc, valve stem, valve core, valve cover, insulation layer, and outer jacket. The valve body features a medium inlet and outlet. The valve stem extends through the valve body and is attached to the valve disc at its lower end. The bottom of the valve disc is equipped with a thermal insulation layer. The valve cover is mounted atop the valve body and is linked to the pneumatic quick-opening actuator via a support bracket.

Figure 1 Structure of the Pneumatic Quick-Opening Shut-Off Valve

1. Valve Body 2. Jacket 3. Lower Protector Plate 4. Insulation Layer 5. Valve Disc 6. Core 7. Valve Stem 8. Valve Cover 9. Bracket 10. First Nut 11. Second Nut

Figure 2 Pneumatic Drive Unit

1. Cylinder base 2. Cylinder 3. Piston 4.Top cover 5. Cover plate 6. Quick exhaust actuator 7. Pressure plate 8. Damping spring

9. Spring

The portion of the valve stem that extends into the valve body is designed as a hollow structure, with a coaxial core mounted inside. A designated clearance between the valve stem and the core creates an annular flow channel, which connects to the core’s internal passage. The valve stem’s outer surface is equipped with two nuts: the first nut interfaces with the core’s internal passage, while the second nut connects to the annular channel. The valve disc features an internal water-receiving chamber that connects both the annular channel and the core’s internal passage, ensuring smooth fluid flow. The valve body is enclosed within a jacket, which includes an external water pipe connection port for thermal regulation. The pneumatic drive unit mainly comprises a piston, cylinder, top cover, cover plate, quick-release actuators, and a spring. The cylinder, which includes the cylinder seat, piston, and spring, serves as the primary actuating component. A cover plate is installed atop the cylinder, with multiple quick-release actuators mounted in parallel above it. A secondary cover plate with multiple vent holes is positioned between the top cover and the actuators. A strip-shaped channel on the inner side of the top cover connects these vent holes, ensuring coordinated airflow. The underside of the valve disc is equipped with a thermal insulation layer and a protective lower guard plate. By integrating a quick-release actuator on the top cover that connects to the internal cavity, the pneumatic drive unit achieves dual-channel separation for air intake and exhaust, allowing rapid evacuation of compressed gas from the cylinder. This design ensures fast valve actuation, smooth piston movement, and stable operation.

To satisfy the specific operational requirements of this valve, it must handle high-temperature airflow capable of producing high-frequency pulse fluctuations. The valve is required to achieve an opening response time of 20 ms, a closing response time of 80 ms, and an on/off cycling frequency of up to 450 cycles per minute. Because conventional high-temperature quick valves cannot achieve the required 20 ms response, a pneumatic quick-opening shut-off valve is installed upstream to enable rapid actuation. First, the switching frequency of the electric high-temperature quick valve is stabilized at 450 Hz. Next, the pneumatic quick shut-off valve opens within 20 ms, allowing the high-temperature airflow to immediately enter the electric valve, thereby enabling rapid start-up. The resulting 450-pulse airflow provides the necessary pulsating flow to support downstream equipment. To enable rapid piston movement, the compressed air above the piston must be released within a specified timeframe. To achieve this, a large exhaust passage is incorporated into the top cover, with a cover plate welded on containing eight through-holes, each equipped with a specially designed rapid-exhaust actuator. When the two-position, three-way solenoid valve is de-energized, the air trapped inside the cylinder is released through the solenoid valve, reducing internal pressure. This rapid venting is facilitated by the quick-exhaust actuator. The actuator’s core is constructed from a highly elastic rubber layer reinforced with steel wire, providing both strength and enhanced safety. As the airflow moves forward, the sealing frame shifts to the right, opening a new air inlet and allowing compressed air to flow in freely. As the gas pressure rises, the piston overcomes the spring force, the pressure of the medium, packing friction, and the sealing force of the valve disc, thereby closing the valve and ensuring a reliable seal.

For proper operation, the pneumatic quick-opening shut-off valve must maintain a reliable seal when closed. During valve closure, the cylinder must overcome three opposing forces: the valve disc’s sealing force, the force exerted by the gas medium on the valve disc, and the spring force. If the force generated by the piston exceeds the combined effect of these three resisting forces, the valve will close effectively and maintain a reliable seal. Strict compliance with the designed intake and exhaust principles ensures rapid valve actuation. The total force acting on the pneumatic quick-opening shut-off valve can be calculated using the following formula:

Where:

F — Force exerted by the medium (N)

P — Pressure on the medium contact surface (Pa)

S — Contact area (m²)

D — Diameter of the medium flow path (m)

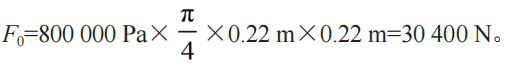

Given a gas pressure of 800,000 Pa acting on a piston with a diameter of 0.22 m, the theoretical force generated by the piston is:

Assuming a transmission efficiency of 0.9, the effective force generated by the piston is:

After calculation, ![]()

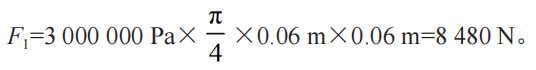

The gas pressure acting on the valve disc is 3,000,000 Pa, and the bottom orifice diameter is 0.06 m. Therefore, the force F1 exerted by the medium on the valve disc is:

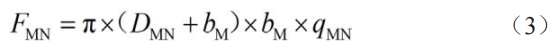

The sealing force of the valve disc FMN can be calculated by:

Where:

FMN — valve disc sealing force (N)

DMN — upper diameter of the valve disc (m)

bM — width of the sealing surface (m)

QMN — specific sealing pressure (N/m²)

The specific sealing pressure is determined by:

Where:

C — sealing material coefficient

PN — working pressure (MPa)

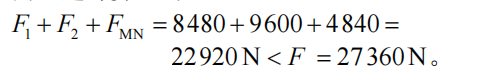

For a valve-disc upper diameter of 60 mm, a sealing-surface width of 15 mm, a working pressure of 3 MPa, and a sealing-material coefficient of 3.5, the calculations yield a specific sealing pressure of 1,670 N and a valve-disc sealing force of 4,840 N. The spring force in the pneumatic quick-opening shut-off valve is 9,600 N.

Therefore, the total resisting force can be expressed as:

The force generated by the piston is sufficient to overcome all opposing forces, ensuring tight closure and reliable sealing of the valve.

The pneumatic quick-opening shut-off valve has a cylinder piston stroke of 40 mm and a compressed-air flow rate of 35 L/s. Before calculating the valve’s start-up time, it is necessary to determine the cylinder volume, the exhaust flow rate of each quick-exhaust actuator, and the total exhaust capacity of the quick-exhaust system (in L/s).

The volume V of compressed gas contained in the cylinder is given by

![]()

Where:

S — cross-sectional area of the cylinder bottom (m²)

h — stroke or height of the cylinder (m)

Given that the flow channel has an inner diameter of 25 mm, with an effective diameter calculated as 22 mm, the instantaneous exhaust flow rate TTT for each quick-exhaust actuator can be expressed as:

v is the medium capacity of the cylinder. According to the design, eight quick-exhaust actuators are arranged in parallel. The total exhaust rate is 106.4 L/s, resulting in a cylinder exhaust time of approximately 0.014 s. The calculations show that the quick-exhaust actuators installed on the top cover of the shut-off valve can rapidly expel the residual compressed air above the piston. This design effectively removes back-pressure damping during piston movement, ensuring the pneumatic shut-off valve opens quickly and operates smoothly.

(1) Petrochemical Industry

Pneumatic quick-opening shut-off valves are extensively used in pipeline transport systems and at storage tank inlets and outlets, thanks to their rapid response and reliable shut-off capabilities. From the point of origin in crude oil or natural gas pipelines to the terminal storage facilities, these valves provide precise control over the flow of fluids such as crude oil, natural gas, and chemical products. In emergency situations, these valves can respond almost instantaneously to cut off fluid flow, effectively preventing accidents and ensuring the safe and stable operation of production processes.

(2) Power Industry

In the power industry, pneumatic quick-opening shut-off valves are mainly used in boiler feedwater and steam pipelines to precisely control the flow of water and steam. They enable accurate flow regulation, ensuring the stable and reliable operation of boiler systems. In emergency or abnormal situations, these valves can immediately halt fluid flow, preventing overpressure or system malfunctions and ensuring the safety and reliability of the entire power generation and supply system.

(3) Metallurgical Industry

In the metallurgical field, pneumatic quick-opening shut-off valves are mainly applied to blast furnace gas and oxygen pipelines. With their rapid response and excellent sealing performance, these valves ensure a stable and reliable supply of blast furnace gas and oxygen during normal operation. In emergencies, they can rapidly isolate the fluid flow to prevent accidents, serving as a vital safeguard for the continuity and safety of metallurgical operations. In addition to the above sectors, pneumatic quick-opening shut-off valves are also widely used in the food processing, pharmaceutical, and environmental protection industries, where they provide dependable flow control performance for a wide range of fluid media.

The pneumatic quick-opening shut-off valve developed in this study, featuring a distinctive pneumatic drive mechanism and an optimized valve body design, delivers rapid response and efficient control even under complex operating conditions. It effectively eliminates the back-pressure damping effect caused by residual gas during valve opening in conventional pneumatic shut-off valves, thereby significantly enhancing the opening speed. Theoretical analysis and calculations confirm that the valve can complete its opening action within 0.014 seconds, fully meeting the stringent response requirements of high-end applications such as wind tunnel testing. Theoretical analysis and calculations confirm that the valve can complete its opening action within 0.014 seconds, fully meeting the stringent response requirements of high-end applications such as wind tunnel testing.

Previous: Flow Field Analysis of a New Control Valve Design

Next: Optimization Design of a Wedge Gate Valve Plate Based on RSM