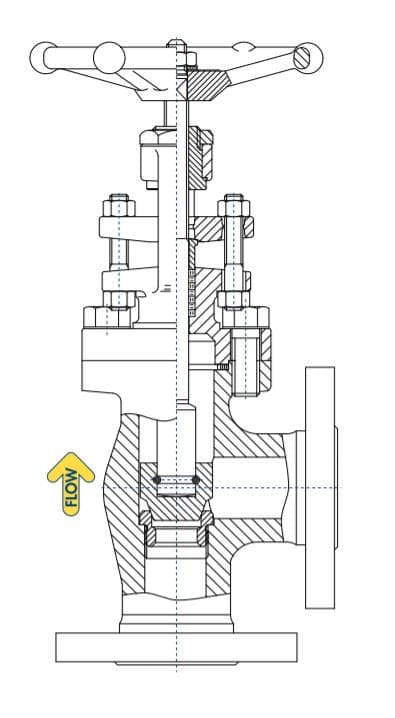

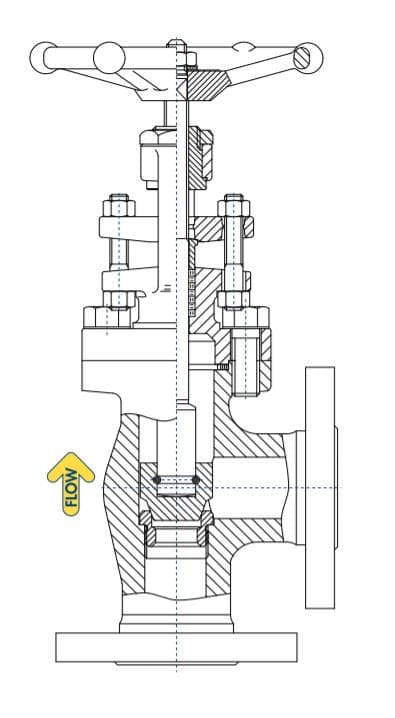

90 Degree Angle Globe Valve, ASTM A182 F304L, 2 Inch, 900 LB

We Provide ASTM A182 F304L Globe Valves, 90 Degree Angle Globe Valves, of Right T Pattern, ASTM A182 F304L, 2 Inch, DN50, 900 LB, PN150, RF, API 602, BS 5352.

Categories

- Globe Valves

Tags

- Right Angle Globe Valves , Angle Globe Valves , 90° Angle Globe Valves

Detail Information

90 Degree Angle Globe Valve

Name: Stainless Steel Globe Valve-Angle Type

Media: Oli, Gas, Water

Size: 2 Inch, DN50

Pressure: Class 900 LB, PN150

Material: ASTM A182 F304L Stainless Steel

Temperature Of Media: -54℃ To 232℃

Feature: 90 Degree Angle Globe Valve, right angle globe valve

Product Range

Normal diameter: 1/4 - 24 Inch (DN8-DN600)

Pressure range: Class 150-2500 LB (PN16-PN420)

Body Material: Carbon steel, Stainless steel, Alloy steel

Standard: API 602, BS 5352, GOST, JIS, DIN, ISO

Power: Manual, Pneumatic, Solenoid, Electrical Actuated

End connection: BW, Flanged

Operation: Handwheel, Gearbox, Electric, Pneumatic

Working temperature: -29℃ - +560℃

ANGLE PATTERN GLOBE VALVES DESIGN is a modification of the basic Tee Pattern Globe valve. The ends of this Globe valve are at an angle of 90 degrees, and fluid flow occurs with a single 90 degrees turn. They have a slightly lower coefficient of discharge than wye-pattern Globe valves. They are applied in periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

The Angle pattern globe valve is a modified version of the "T" - Pattern Globe valve with an inlet and outlet at right angles. When fitted at a change in piping direction, this valve eliminates a bend and has the advantage of a smaller pressure drop than a conventional "T" pattern globe valve. Angle valves have the same stem, disc and seat ring design features as the globe valve. The fundamental difference between the two is that the fluid flow through the angle valve makes a 90° turn. These valves offer less resistance to flow than a globe valve with an elbow which it would replace. An angle valve reduces the number of joints in a line, in addition to saving installation time. They are also used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

Name: Stainless Steel Globe Valve-Angle Type

Media: Oli, Gas, Water

Size: 2 Inch, DN50

Pressure: Class 900 LB, PN150

Material: ASTM A182 F304L Stainless Steel

Temperature Of Media: -54℃ To 232℃

Feature: 90 Degree Angle Globe Valve, right angle globe valve

Product Range

Normal diameter: 1/4 - 24 Inch (DN8-DN600)

Pressure range: Class 150-2500 LB (PN16-PN420)

Body Material: Carbon steel, Stainless steel, Alloy steel

Standard: API 602, BS 5352, GOST, JIS, DIN, ISO

Power: Manual, Pneumatic, Solenoid, Electrical Actuated

End connection: BW, Flanged

Operation: Handwheel, Gearbox, Electric, Pneumatic

Working temperature: -29℃ - +560℃

ANGLE PATTERN GLOBE VALVES DESIGN is a modification of the basic Tee Pattern Globe valve. The ends of this Globe valve are at an angle of 90 degrees, and fluid flow occurs with a single 90 degrees turn. They have a slightly lower coefficient of discharge than wye-pattern Globe valves. They are applied in periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

The Angle pattern globe valve is a modified version of the "T" - Pattern Globe valve with an inlet and outlet at right angles. When fitted at a change in piping direction, this valve eliminates a bend and has the advantage of a smaller pressure drop than a conventional "T" pattern globe valve. Angle valves have the same stem, disc and seat ring design features as the globe valve. The fundamental difference between the two is that the fluid flow through the angle valve makes a 90° turn. These valves offer less resistance to flow than a globe valve with an elbow which it would replace. An angle valve reduces the number of joints in a line, in addition to saving installation time. They are also used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

Next: ASTM A105N Pressure Seal Bonnet Globe Valve, 3/4 IN, 1500 LB

Previous: ASTM A182 F11 Globe Valve, Rising Stem, DN20, PN100, API 602