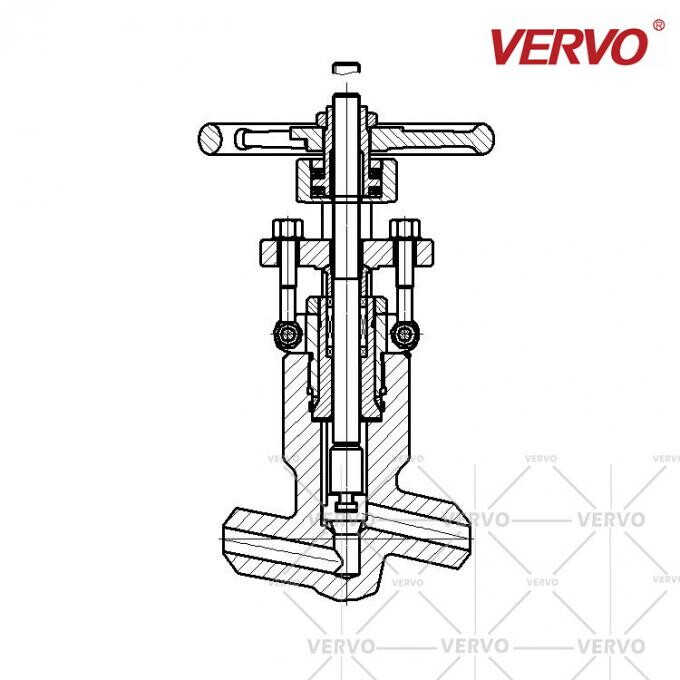

Válvula de cierre del bonete a presión, 2 pulgadas, 2690 libras, API 602

Se encontraron válvulas de cierre de bonete selladas a presión de alta calidad de fabricantes confiables. Estas válvulas de acero forjado están diseñadas para manejar hasta 2690 libras de presión, en línea con los estándares API 602 y BS 5352. Nuestras válvulas son compatibles con una amplia gama de estándares, incluidos GOST, JIS, DIN e ISO, para garantizar una integración perfecta en una variedad de sistemas. Estas válvulas de 2 pulgadas están diseñadas con aletas de guía superiores e inferiores, combinadas con un funcionamiento suave del vástago, para proporcionar confiabilidad y eficiencia a sus aplicaciones industriales.

- Categorías

- Válvulas de Globo

- Etiquetas

Información detallada

Válvula de globo industrial BW Dn502 pulgadas 2690 libras PSB sello de presión bonete forja acero

Name: Forged Steel Power Plant Valve 2690 LB

Media: Oli, Gas, Water

Estándar: API 602, BS 5352, GOST, JIS, DIN, ISO

Presión: 150-800 libras, 1500 libras, 2500 libras

Potencia: manual, neumático, electromagnético, eléctrico

Temperatura media: temperatura media, temperatura normal, alta temperatura, -65 ° F a 450 ° F (-54 ° C a 232 ° C)

Tamaño: 1/4 a 4 pulgadas, DN8-DN100

Características: válvula de globo BW, válvula de globo industrial, válvula de bonete de sello de presión Dn50

Features and Benefits

The VERVO globe valve features a top and bottom-guided disc design that ensures smooth stem operation, free from side thrust induced by high-pressure flow. With a non-rotating stem, friction among moving components is reduced, leading to extended stem packing life. These design elements culminate in effortless operation and reliable shutoff even under the most demanding pressure conditions.

VERVO's proven pressure seal design.

Body-guided disc eliminates side thrust and provides longer disc, seat, and body life.

Impactor handwheel for tight shutoff.

Designed to ASME B16.34.

Body made of superior strength forgings and optional cast steel.

VERVO stem seal offers a tight seal with little to no maintenance over long periods.

Optional live-loading of packing.

Non-rotating stem.

Hardfaced seating faces resist erosion.

Other sizes and pressure classes are available.

The central component of the pressure seal globe valve incorporates a pressure self-tightening structure, ensuring optimal sealing performance even in environments of high pressure and temperature. Typically, the sealing ring is available in two materials: low-carbon steel or a combination of flexible graphite and SS 316. Additionally, the sealing surface is fortified with hard alloy through welding, creating a metal layer with a thickness of at least 3mm. This construction imbues the valve with exceptional wear resistance, temperature resilience, and corrosion resistance, significantly extending its operational lifespan.

Both ends of the valve feature a welding structure, with the dimensions of the welding groove customizable according to client specifications. This valve is suitable for handling various media, including high-temperature and high-pressure water, steam, oil products, and superheated steam. Consequently, it finds widespread application across industries such as thermal power plants, petrochemicals, metallurgy, and other industrial sectors.

Main Features

The central connection adopts a pressure self-tightening structure.

The disc and seat are welded with hard alloy.

High-temperature creep resistance design.

The material of the stem is precipitation hardening stainless steel by nitriding.

Operating devices can be manual, gear, bevel gear, and electric actuators.

Main Parts and Materials

Name: Forged Steel Power Plant Valve 2690 LB

Media: Oli, Gas, Water

Estándar: API 602, BS 5352, GOST, JIS, DIN, ISO

Presión: 150-800 libras, 1500 libras, 2500 libras

Potencia: manual, neumático, electromagnético, eléctrico

Temperatura media: temperatura media, temperatura normal, alta temperatura, -65 ° F a 450 ° F (-54 ° C a 232 ° C)

Tamaño: 1/4 a 4 pulgadas, DN8-DN100

Características: válvula de globo BW, válvula de globo industrial, válvula de bonete de sello de presión Dn50

| Model number | J61Y-P54/2500 LB |

| Item | Globe Valve |

| Certification | ISO 9001, ISO 14001, ISO 18001, TS, CE, API |

| Connection form | Butt Welding |

| Body material | Forged Steel 12CrMoV |

| Seal material | Gasket |

| Feature | Easy disassembly and assembly |

Features and Benefits

The VERVO globe valve features a top and bottom-guided disc design that ensures smooth stem operation, free from side thrust induced by high-pressure flow. With a non-rotating stem, friction among moving components is reduced, leading to extended stem packing life. These design elements culminate in effortless operation and reliable shutoff even under the most demanding pressure conditions.

VERVO's proven pressure seal design.

Body-guided disc eliminates side thrust and provides longer disc, seat, and body life.

Impactor handwheel for tight shutoff.

Designed to ASME B16.34.

Body made of superior strength forgings and optional cast steel.

VERVO stem seal offers a tight seal with little to no maintenance over long periods.

Optional live-loading of packing.

Non-rotating stem.

Hardfaced seating faces resist erosion.

Other sizes and pressure classes are available.

The central component of the pressure seal globe valve incorporates a pressure self-tightening structure, ensuring optimal sealing performance even in environments of high pressure and temperature. Typically, the sealing ring is available in two materials: low-carbon steel or a combination of flexible graphite and SS 316. Additionally, the sealing surface is fortified with hard alloy through welding, creating a metal layer with a thickness of at least 3mm. This construction imbues the valve with exceptional wear resistance, temperature resilience, and corrosion resistance, significantly extending its operational lifespan.

Both ends of the valve feature a welding structure, with the dimensions of the welding groove customizable according to client specifications. This valve is suitable for handling various media, including high-temperature and high-pressure water, steam, oil products, and superheated steam. Consequently, it finds widespread application across industries such as thermal power plants, petrochemicals, metallurgy, and other industrial sectors.

Main Features

The central connection adopts a pressure self-tightening structure.

The disc and seat are welded with hard alloy.

High-temperature creep resistance design.

The material of the stem is precipitation hardening stainless steel by nitriding.

Operating devices can be manual, gear, bevel gear, and electric actuators.

Main Parts and Materials

| Part Name | Material Mark | |||

| Body | WCB | WC1 | WC6 | WC9 |

| Disc | WCB | WC1 | WC6 | WC9 |

| Seat | 25 | 15CrMoA | 12Cr1MoVA | 12Cr1MoVA |

| Stem | 1Cr17Ni2 | 1Cr17Ni2 | SUH600 | SUH600 |

| 20Cr1Mo1V1A | 20Cr1Mo1V1A | |||

| Cover | 25 | 15CrMoA | 12Cr1MoVA | 12Cr1MoVA |

| WCB | WC1 | WC6 | WC9 | |

| Packing | Reinforced flexible graphite | |||

| Yoke | WCB | WCB | WCB | WCB |

| WC1 | WC6 | WC9 | ||

| Sealing ring | Mild steel(reinforced flexible graphite) | Mild steel | Mild steel | |

| Stem Nut | 45 | |||

| Suitable temp. | ≤425 °C | ≤450 °C | ≤540 °C | ≤570 °C |

|

|

Siguiente: Válvula de cierre de brida ASTM A105N, 1 pulgada, 300 libras, API 602

Anterior: Válvula de cierre sin perno ASTM A182F304, 1 pulgada, 800 libras, API 602